Pro

From Scan to Robot Path in Minutes

—no code, no CAD required.

Captures Real Part Geometries

Fast and precise 3D scanning removes reliance on CAD models

Automated Calibration

Replaces manual, time-consuming calibration with fully automated setup

Compensates for Misalignment

Adapts motion paths to correct for positional and angular part deviations

The Pro workflow for your operation

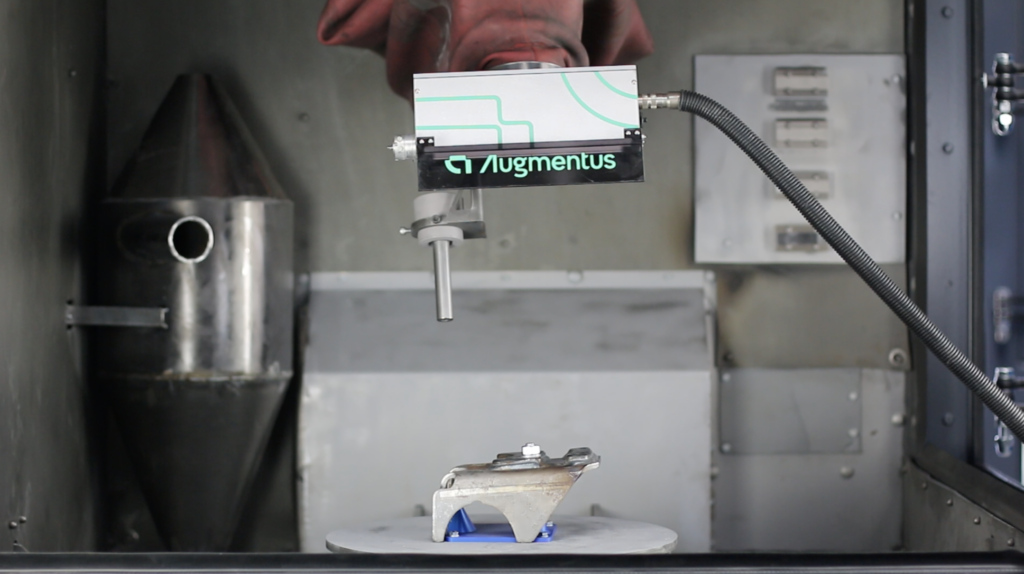

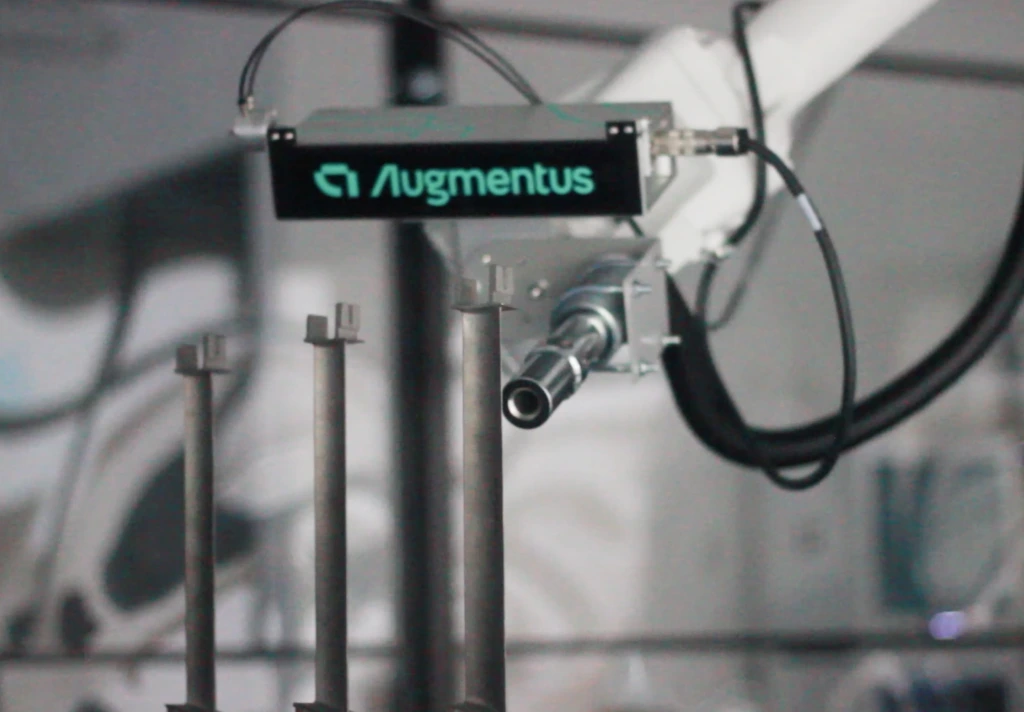

Vision Scanners

of Workpiece

Robot Motion

24X Faster

compared to conventional methods

PRO Workflow ~30 MINS

Manual Scanning & Programming 9-12 HRS

See Precisely. Align Perfectly. Adapt Instantly.

Vision Capabilities

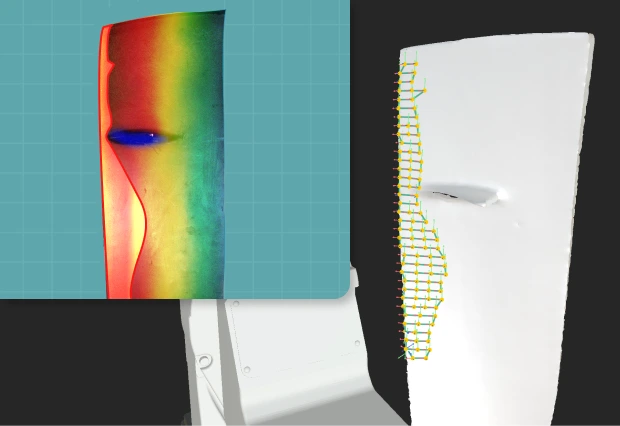

Rapid 3D Reconstruction for Complex Workpieces

Generate precise toolpaths from real-world parts—Augmentus delivers fast, reliable 3D reconstruction to handle complexity, reduce setup time, and eliminate guesswork in high-mix production.

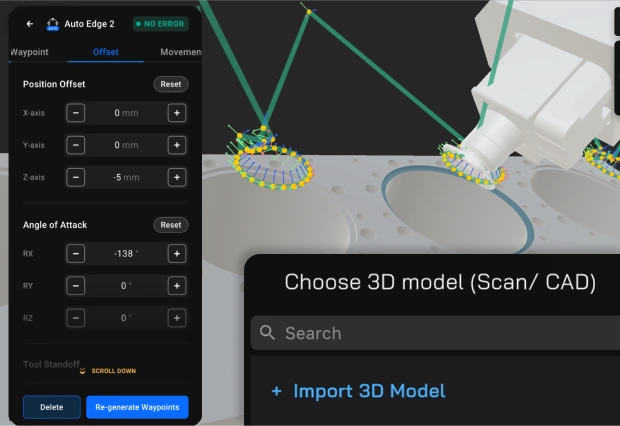

Automated Workpiece Calibration

One-time easy calibration eliminates tedious 3-point methods, reducing setup time and minimizing manual error.

3D Reconstruction in minutes

Quickly converts scanned point clouds into mesh models for visualization and precise toolpath generation.

Preset Scan Parameters

Uses predefined settings for material and part type to speed up setup and ensure consistency across jobs.

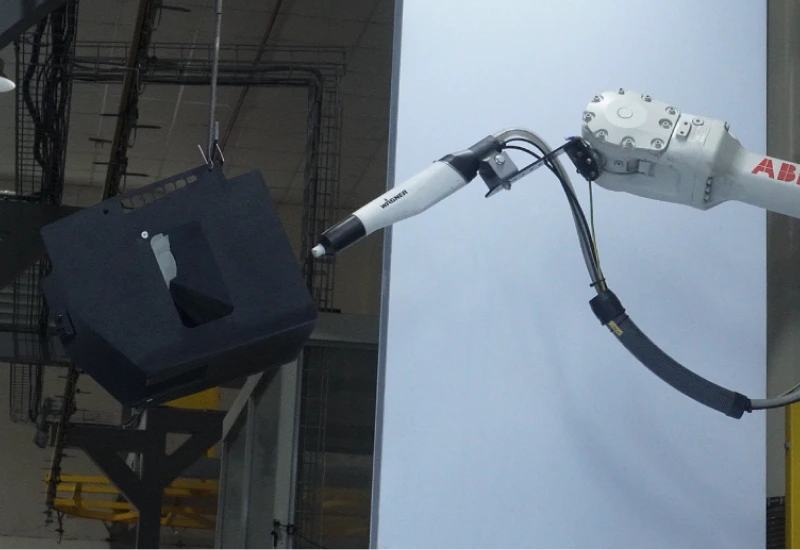

Flexible Mounting Options

Supports robot-mounted or fixed setups for adaptable scanning across different workspaces and part types.

Supports Rotary Scans

Enables continuous capture with rotating fixtures or positioners for cylindrical or symmetrical parts.

Multi-angle Stitching

Combines multiple scan angles into one complete 3D model for full surface coverage and accuracy.

Accurate Scanning for Every Geometry

Metallic parts with shiny surfaces such as turbine blades

Large aerospace wingtip with ceiling mounted robot

Large metal fabricated part on rotary table

Automotive parts such as car bumper

Motor fuel tank with multiple curvatures and holes

Vision Intelligence

Positional and/or Rotational Deviation Compensation

Conventional setups require costly fixtures and manual adjustments.

Augmentus compensates for positional and rotational variations, enabling precise processing without manual alignment.

No Fixtures Required

Adjusts path to real-world part location

Faster Changeovers

Avoids re-teaching robots between SKUs

Higher Process Accuracy

Eliminates misalignment-driven quality issues

Includes All Core Capabilities

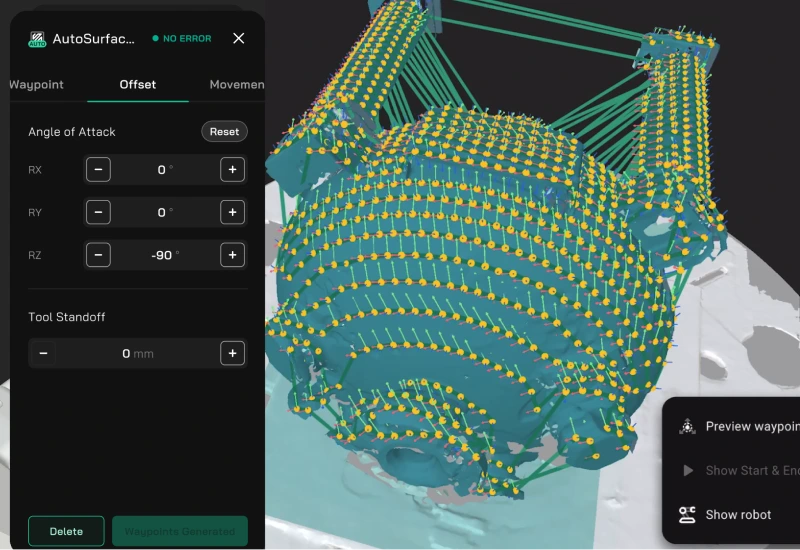

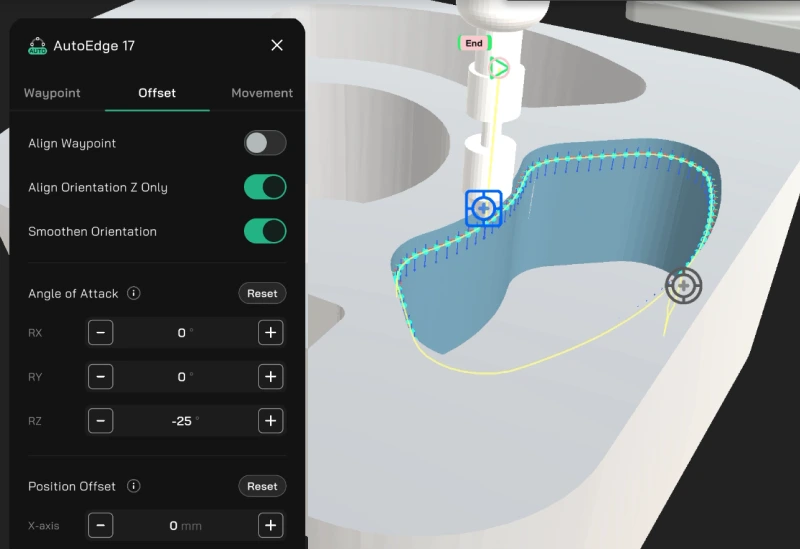

AutoGenerate Toolpaths for any Geometry

Automatically map optimized toolpaths onto complex surfaces for complete and consistent motion.

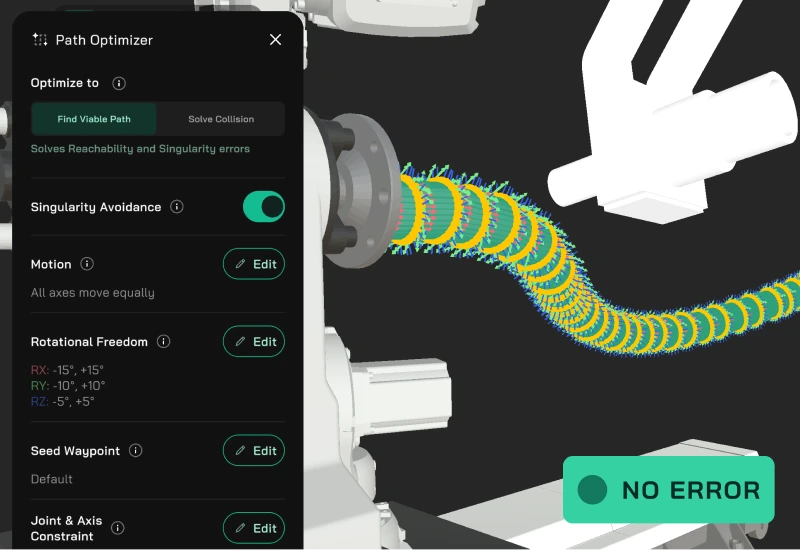

Path Optimization for Error-Free Motion

Actively analyzes the robot’s kinematics to detect approaching singularities and adapts the robot path automatically.

Easy Process Parameter Controls

Define process parameters through an intuitive 3D interface, ensuring repeatable robot operations without coding.

And more...

- Hole Avoidance

- Operator vs Editor Mode

- Template Manager

- Custom Tool Integration

- Back up & Restore

“Augmentus’ 3D scanning and AI-powered path planning technology complement our expertise in shot peening, resulting in systems that are easier to deploy, faster to set up, and capable of handling a wide variety of parts with confidence.”

— Volker Schneidau, Managing Director, sentenso GmbH

Setup & Integration

Supports External Axes

Compatible with multi-axis set up. This includes linear rail, turntables, and/or positioner.

Flexible Integration: Retrofit or Turnkey

Whether you’re upgrading existing robots or investing in new setups, Augmentus has you covered.

Compatible with Major OEMs

Augmentus supports a wide variety of robot brands, sensors, and equipment for seamless integration.

Applications

See Augmentus in Action

Explore how we automate real-world applications with precision and speed

Available in Pro

3D reconstruction for full surface

autopath generation

positional deviation compensation

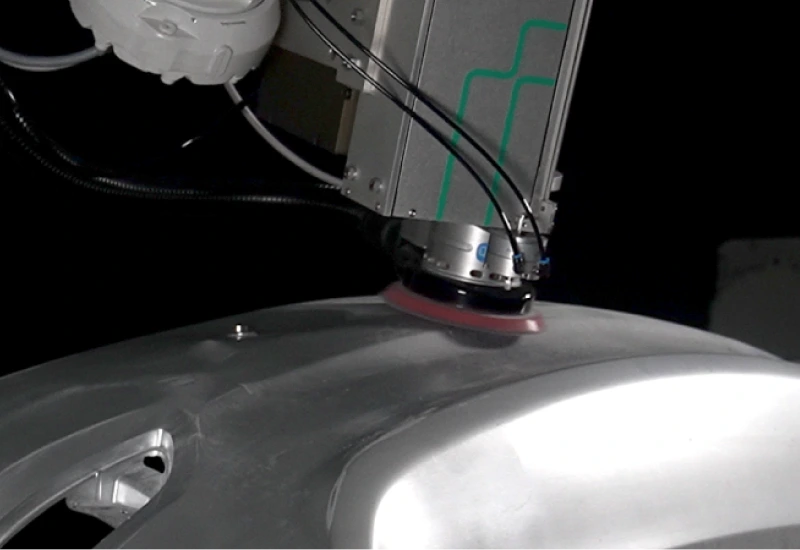

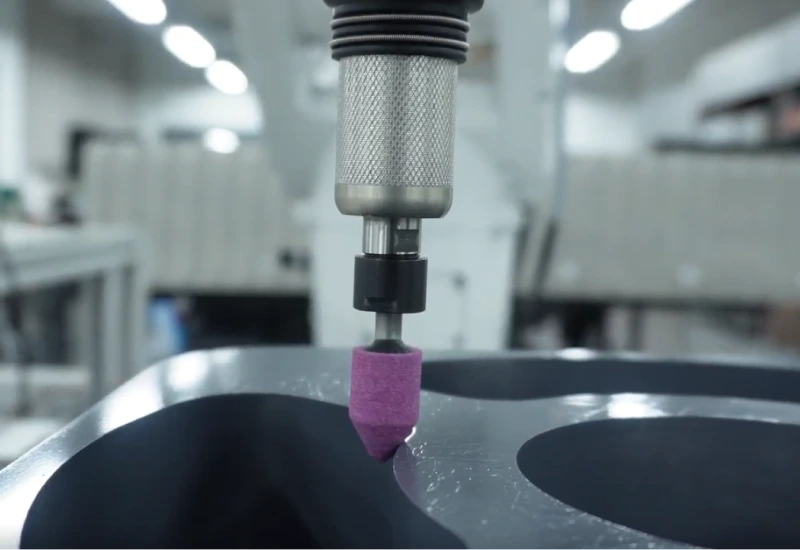

Sanding

Surface leveling or paint prep on large/curved geometries

Grinding

Post-weld or dimensional correction

Polishing

High-finish aesthetic or functional surface finishing

Deburring

Edge cleanup after casting, welding or machining

Available in Pro

scan to mesh technology

autopath generation for targeted areas

offline simulation with spray visualization

Shot Peening

Propelling media to induce compressive surface stress and improve strength

Blasting

Abrasive media cleaning or surface preparation

Thermal Spraying

High-velocity coating deposition for wear/corrosion resistance

Painting & Coating

Automated paint or coating application

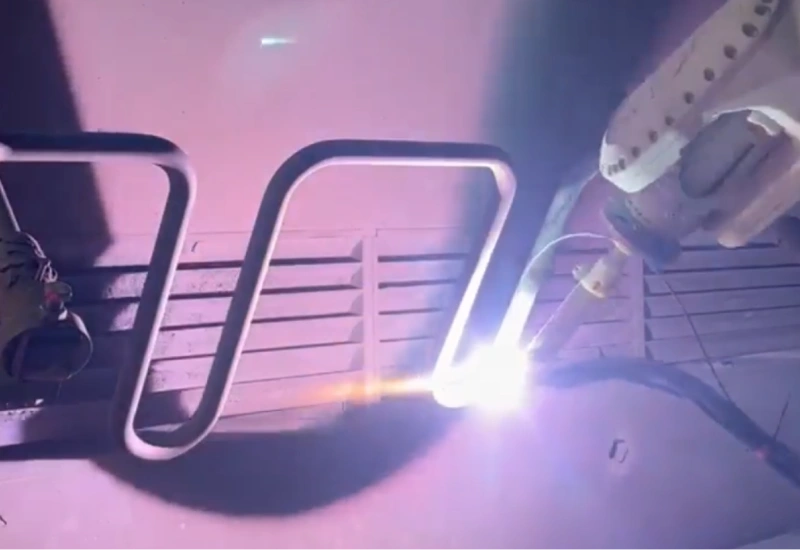

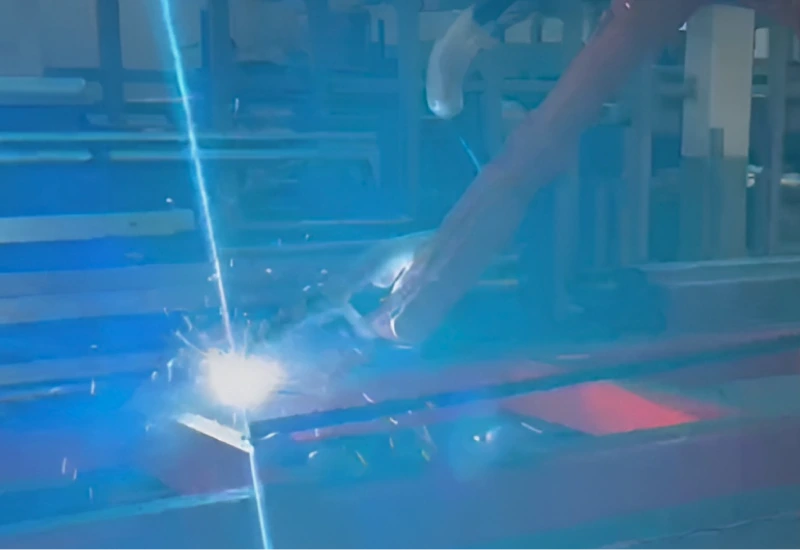

Available in Pro

edge detection & path generation

weaving pattern selection

smart collision avoidance

Arc Welding

Wire/arc based joining or multi-pass repair

Laser Welding

Precision low heat-input joining with minimal HAZ

Cladding

Deposition of overlay material (wire or powder) for wear/corrosion repair

Additive Manufacturing

Material build-up using wire feed and arc energy for repair [Coming soon]

Use Cases

Autonomous Sandblasting for Aerospace MRO — How Augmentus Unlocks High-Mix, Rapid-Turnaround Operations

Industry Context Aerospace Maintenance, Repair, and Overhaul (MRO) companies face one of the most extreme forms of high-mix, high-variability manufacturing. […]

Building the Future of Scalable Automation: Augmentus x sentenso

Augmentus is proud to be a strategic partner of sentenso, a leading solution provider with deep expertise in shot peening […]

How Augmentus Automated Turbine Blade Maintenance for Aerospace – No Programming Needed

Related Products

Explore Other Products for Your Needs

Core

Essential for Rapid Path Generation

Automate industrial robots without code using intuitive offline path planning.

Auto

Closed-Loop System

Auto combines Augmentus’ proprietary advanced perception intelligence and AI model to manufacturing variation autonomously.

Need Expert Guidance Before Choosing?

Discuss your requirements with our automation experts to find the perfect fit.