Core

Easiest and Fastest way to

Program Robots

No-Code Programming

Rapid Part Set-Up

Offline Simulation

The Core workflow for your operation

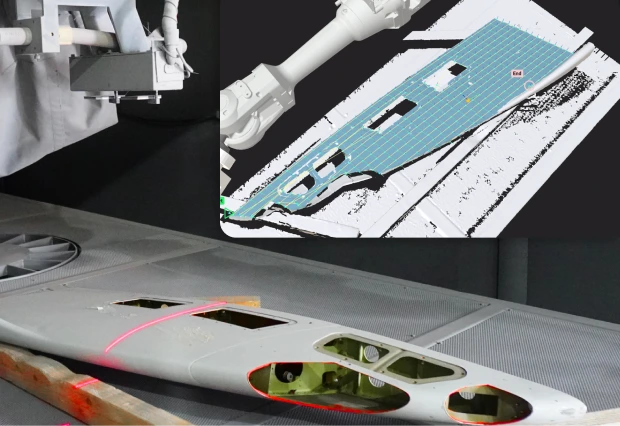

3D Scanner

Robot Motion

24X Faster

compared to conventional methods

Core Workflow ~15-30 MINS

Manual Programming 4-6 HRS

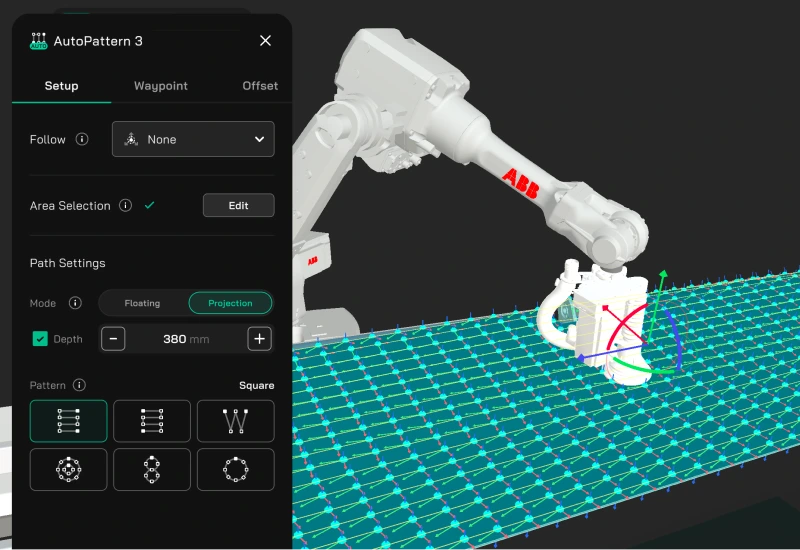

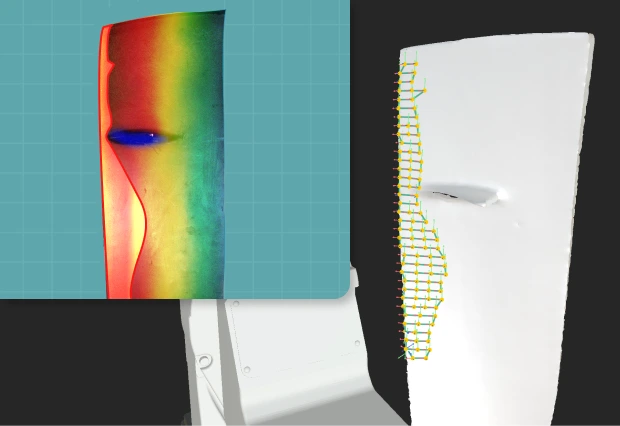

Auto-Generate Toolpaths for any Geometry

For Predefined Motion Patterns

Applies repeatable path patterns over surfaces, adapting to geometry and process needs.

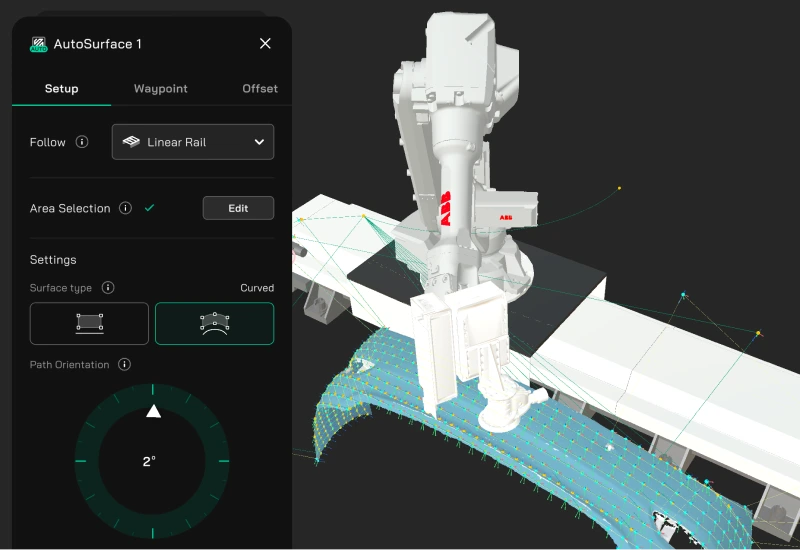

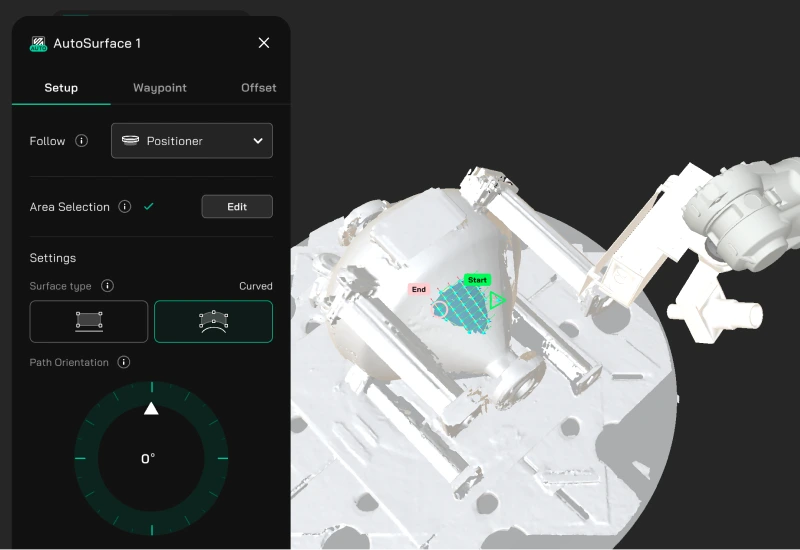

For Full Surface Coverage

Automates toolpath generation for any 3D surface, ensuring uniform coverage and optimal path efficiency.

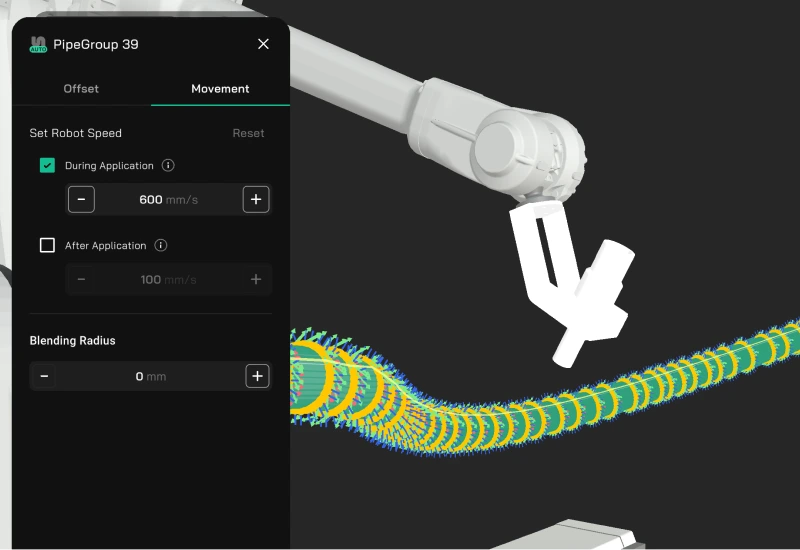

For Complex Edges

Traces edges and seams accurately, ideal for welding, sealing, or edge-based applications.

For Cylindrical Objects

For Targeted Areas

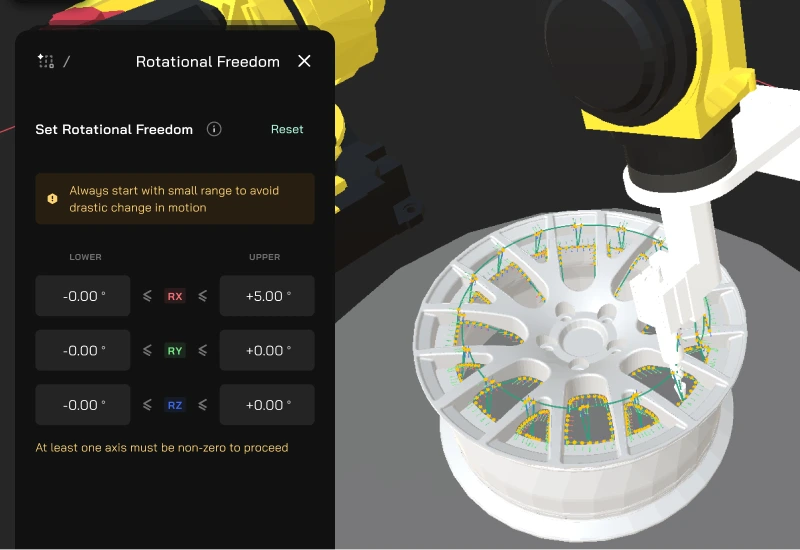

Path Optimization for Precise & Error-Free Motion

Multi-Axis movement

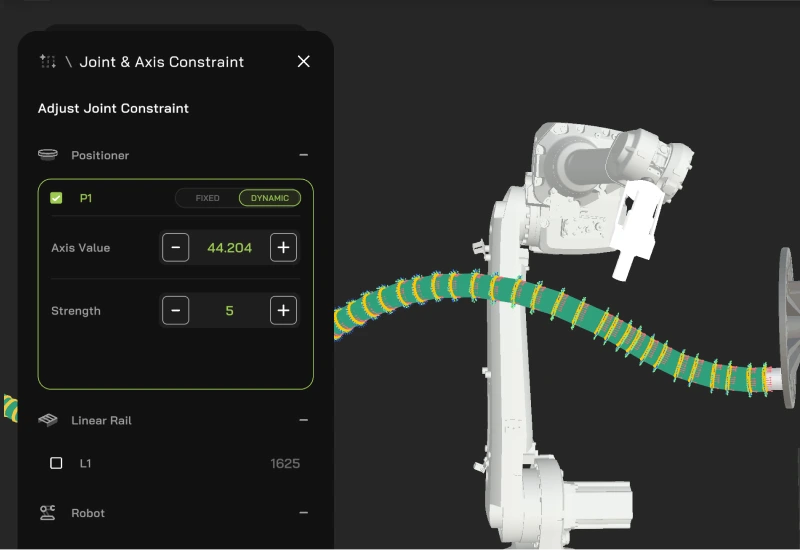

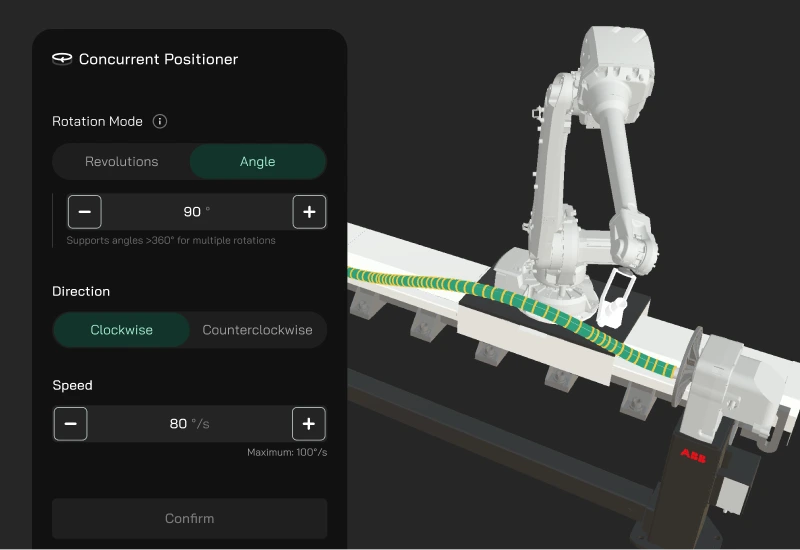

Coordinated Motion Across All Axes

Augmentus synchronizes motion between the robot and all connected external axes such as linear rails and positioners to maintain smooth, continuous path trajectories while engaging multi-axis coordination to achieve full coverage.

Synchronous Axis Planning

Computes motion across all robot and external axes together to ensure smooth, fluid trajectories.

Motion Presets for Setups

Offers customizable motion strategies—like rail-prioritized movement—to suit different configurations.

Kinematic Optimization

Distributes movement across available axes to minimize strain, avoid lock-ups, and extend mechanical lifespan.

No room for error

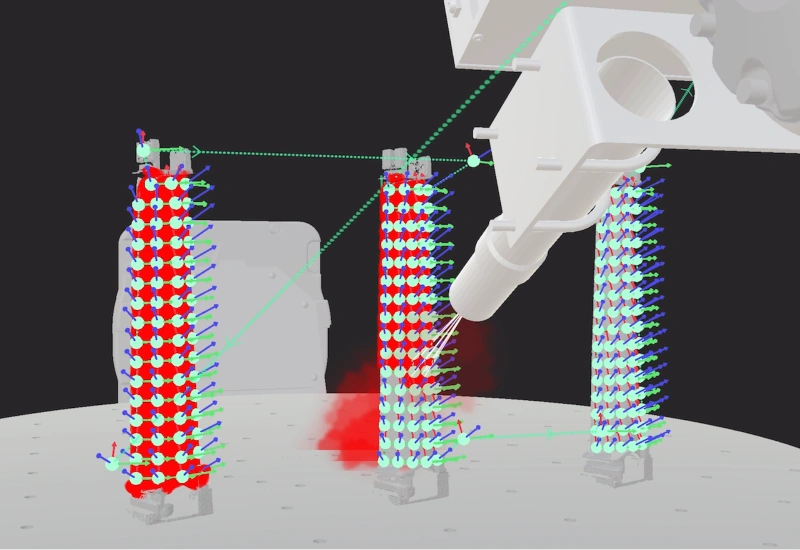

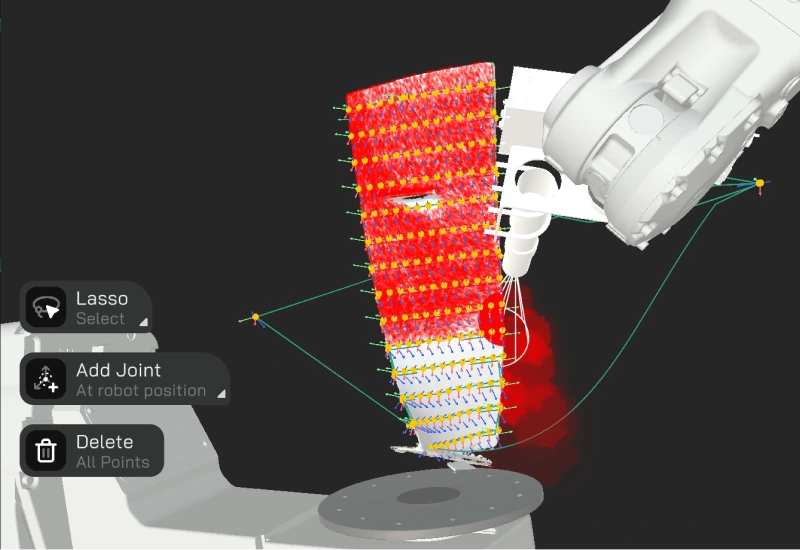

Collision and Singularity Avoidance with Intelligent Path Optimization

Automatically detects and resolves kinematic constraints, collisions, and singularities—ensuring smooth, continuous robot motion across complex geometries.

Singularity-Free Motion

Allows users to define acceptable tool and joint angles to avoid singularities and maintain smooth, uninterrupted robot motion.

Collision-Aware Planning

Detects potential collisions and recalculates safe robot paths, liminating manual troubleshooting and improving cell safety.

Joint Constraint Support

Respects wrist locking, cable protection, and rail-prioritized motion constraints to maintain mechanical integrity and motion reliability.

"When we started this project, I had no idea about robot teaching, but with Augmentus’ training and support, I am now able to generate the painting program with confidence. Augmentus is extremely easy to use."

— Đinh Thúc Vĩnh, Technical manager industrial solutions, j. wagner co. ltd.

SIMULATION CAPABILITIES

Advanced Offline Simulation for Fast and Risk-Free Deployment

Visualize and verify toolpaths before execution—minimizing downtime and setup errors.

Spray Visualization

Simulates realistic spray behavior to fine-tune process parameters and validate surface coverage.

Multi-Axis Robot Paths

Simulate full multi-axis robotic systems—including concurrent positioners, gantries, and linear tracks—with accurate kinematics and synchronized motion, even at high speeds.

Conveyor Tracking

Preview dynamic part movement along a conveyor to ensure correctly timed toolpaths, and precise process execution for moving workpieces.

Environment Collision Detection

Import CAD models of your workcell and define safety boundaries to ensure collision-free motion planning that reflects your real setup.

Extended Features

Hole Avoidance

Auto-segments holes to ensure accurate motion

Operator vs Editor Mode

Switch between operation and advanced editing modes

Template Manager

Save and reuse project templates easily

Custom Tool Integration

Integrate custom tools with user-defined API commands

Back Up & Restore

Quick sharing of stations and projects with seamless transfer

Recipe

Organize and process-specific parameters for repeatable tasks

Applications

See Augmentus in Action

Explore how we automate real-world applications with precision and speed

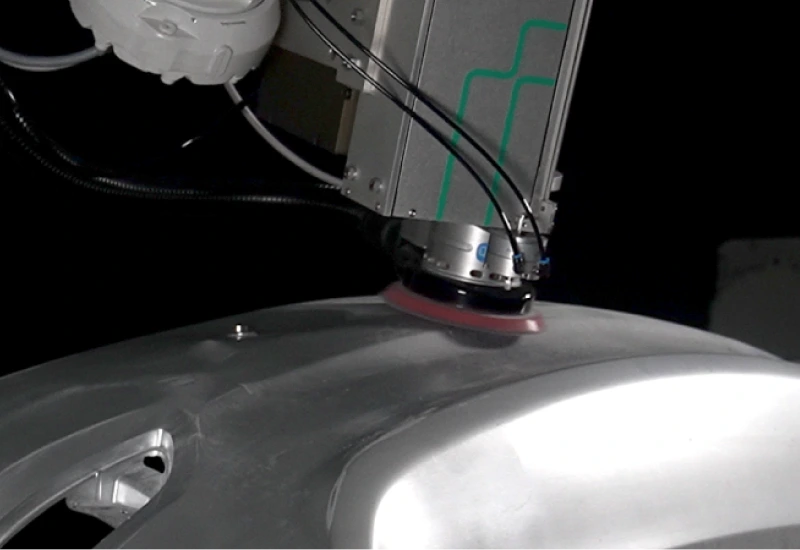

Available in Core

autopath generation for full surface

force compliance enabled

hole avoidance technology

Sanding

Surface leveling or paint prep on large/curved geometries

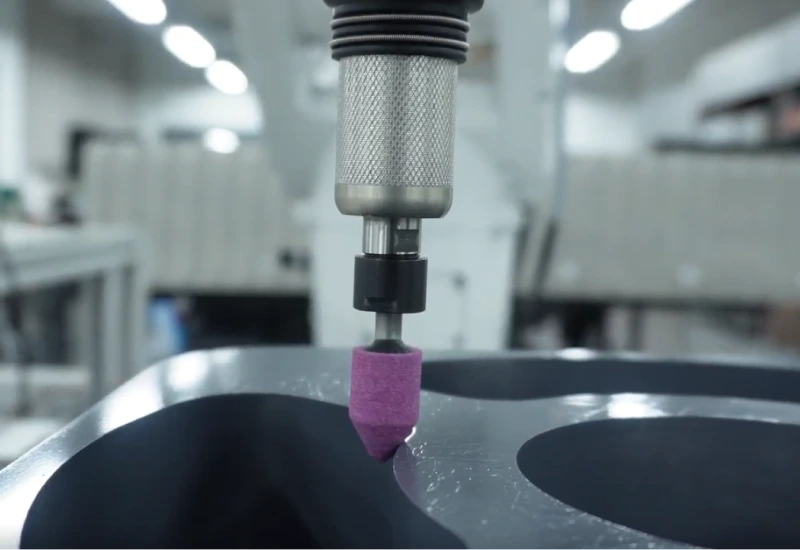

Grinding

Post-weld or dimensional correction

Polishing

High-finish aesthetic or functional surface finishing

Deburring

Edge cleanup after casting, welding or machining

Available in Core

autopath generation for targeted areas

conveyor tracking enabled

offline simulation with spray visualization

Shot Peening

Propelling media to induce compressive surface stress and improve strength

Blasting

Abrasive media cleaning or surface preparation

Thermal Spraying

High-velocity coating deposition for wear/corrosion resistance

Painting & Coating

Automated paint or coating application

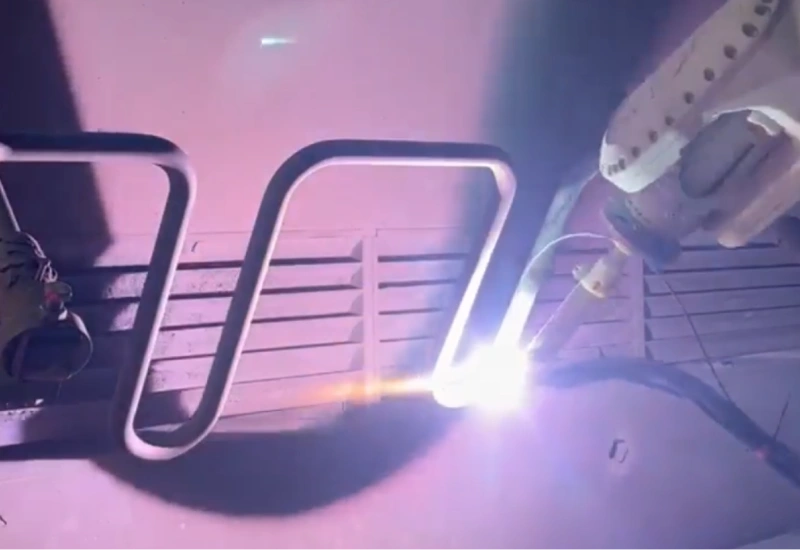

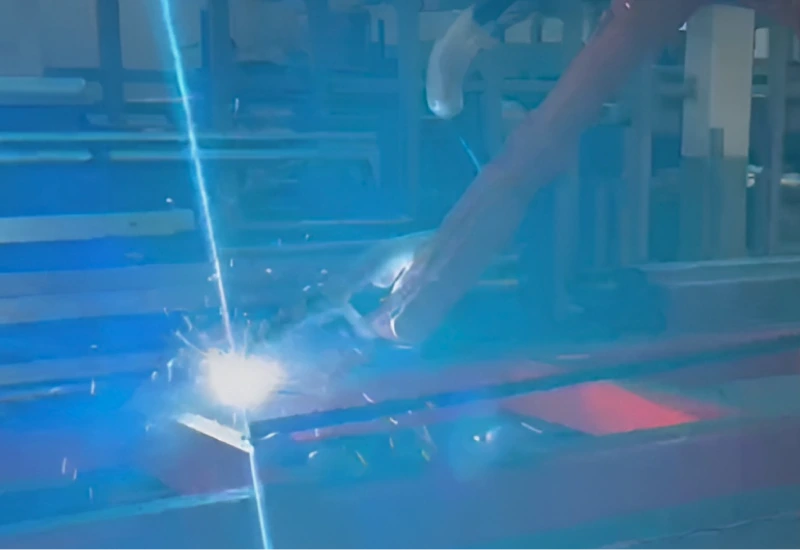

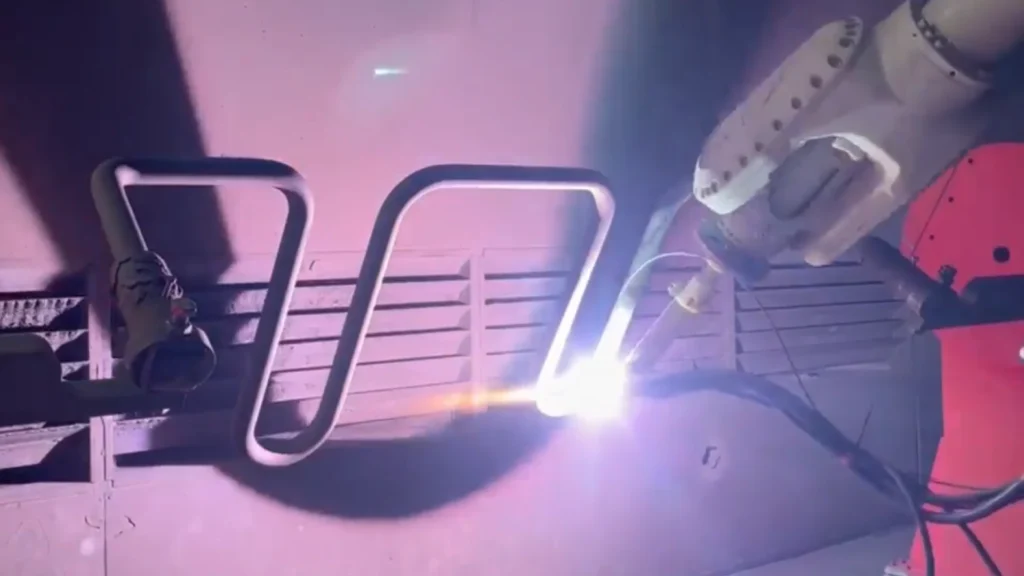

Available in Core

edge detection & path generation

weaving pattern selection

smart collision avoidance

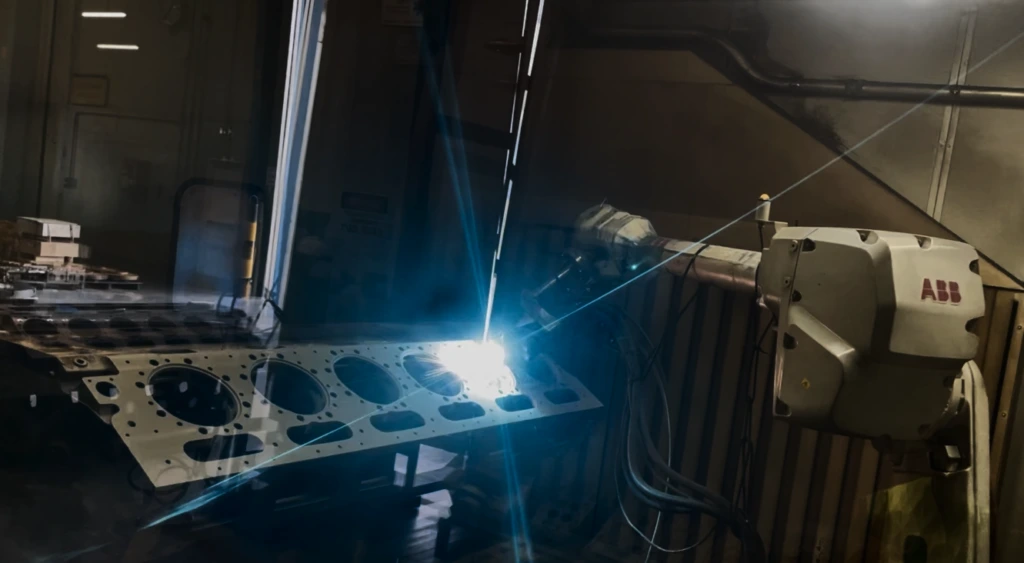

Arc Welding

Wire/arc based joining or multi-pass repair

Laser Welding

Precision low heat-input joining with minimal HAZ

Cladding

Deposition of overlay material (wire or powder) for wear/corrosion repair

Additive Manufacturing

Material build-up using wire feed and arc energy for repair [Coming soon]

Use Cases

Automated Thermal Spraying for Bent Pipes: Faster Programming with AutoPath

Overview Thermal spraying of bent or curved pipes traditionally requires extensive robot programming to ensure correct spray angles, stand-off distances, […]

The True Cost of Teach Pendant Programming in a High-Mix Manufacturing Landscape

Introduction Industrial robots have transformed manufacturing by automating repetitive and hazardous tasks. For decades, teach pendant programming has been the […]

Automotive Engine Block Repair with Robotic Thermal Spraying: Programming in Minutes with Scan To Path Technology

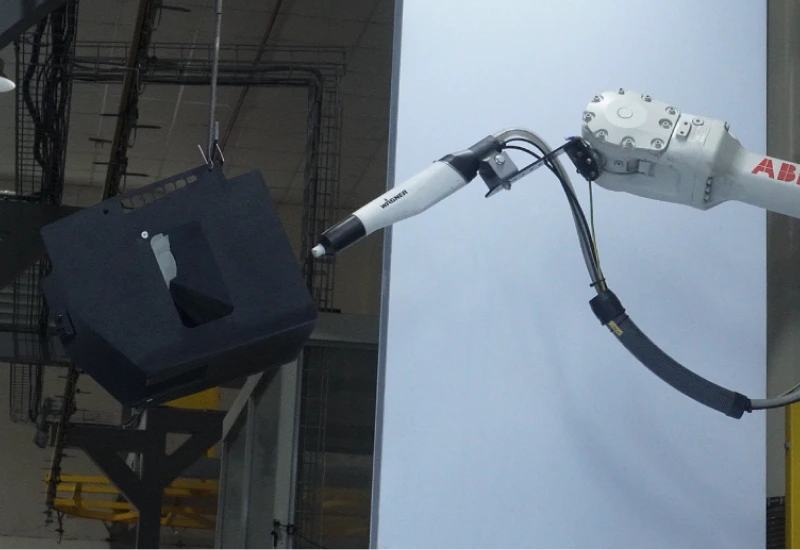

Setup & Integration

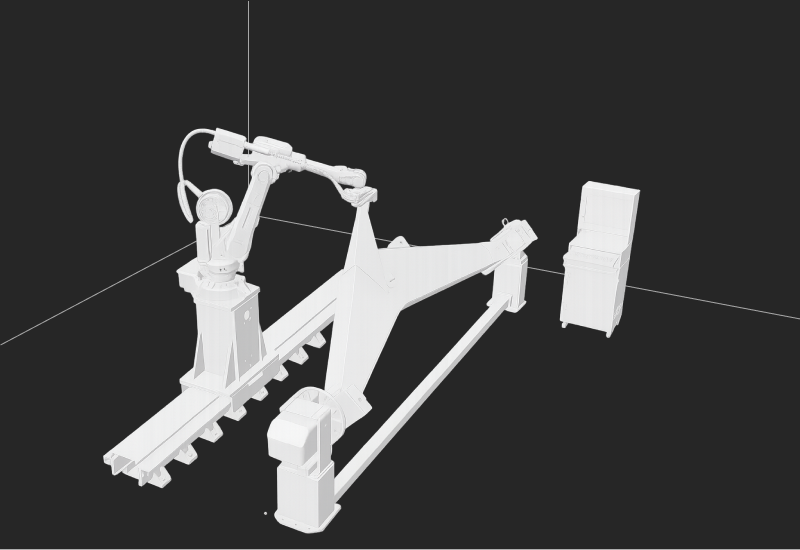

Supports External Axes

Compatible with multi-axis set up. This includes linear rail, turntables, and/or positioner.

Flexible Integration: Retrofit or Turnkey

Whether you’re upgrading existing robots or investing in new setups, Augmentus has you covered.

Compatible with Major OEMs

Augmentus supports a wide variety of robot brands, sensors, and equipment for seamless integration.

Upgrade options

Explore More Advanced Products

Unlock additional automation capabilities with 3D vision and adaptive control

Pro

Vision-Guided Automation

Pro adds 3D scanning and calibration, allowing automation of parts with setup or shape variation — without CAD reliance.

Auto

Closed-Loop System

Auto combines Augmentus’ proprietary advanced perception intelligence and AI model to manufacturing variation autonomously.

Need Expert Guidance Before Choosing?

Discuss your requirements with our automation experts to find the perfect fit.