Automate Complex Surface Treatment

and Spraying Processes

Watch Video

2 min.

the augmentus approach to robotic programming

Digitize Workpiece

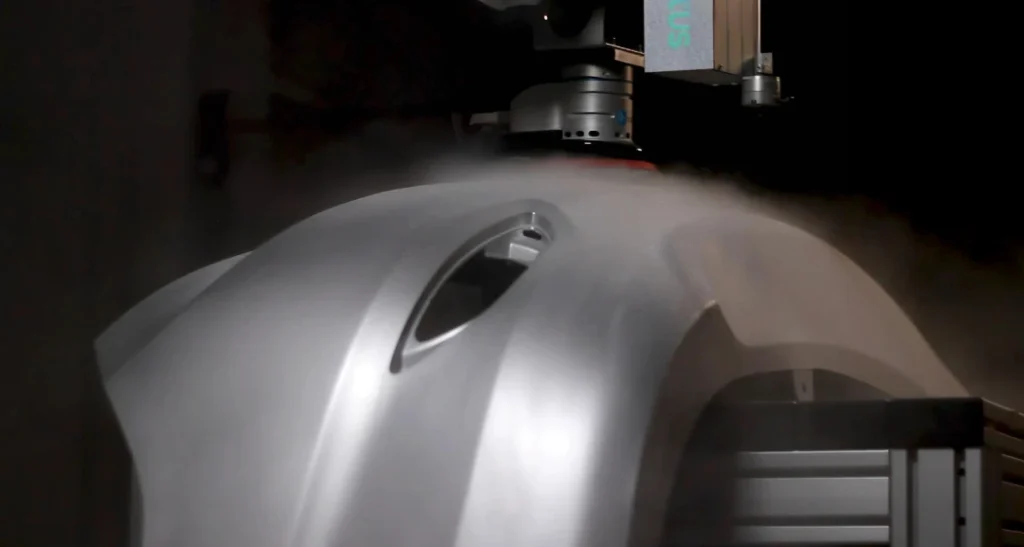

Capture 3D models or import CAD files to map shapes and contours for precise robotic programming.

Auto-Generate Spray Paths

Generate optimized robot toolpaths and simulate robot motion before deployment.

Deploy Adaptive Spraying

Deploy adaptive robot motion that identifies part-to-part deviations for precise and consistent execution.

Built for Spraying Automation

Rapid Generation of Spray Paths with Easy Adjustment of Process Parameters

Digitize workpieces for accurate and efficient toolpath generation. Leverage an intuitive interface to precisely adjust parameters such as tool standoff, step distance, and angle of attack, ensuring uniform coating and optimal spray results.

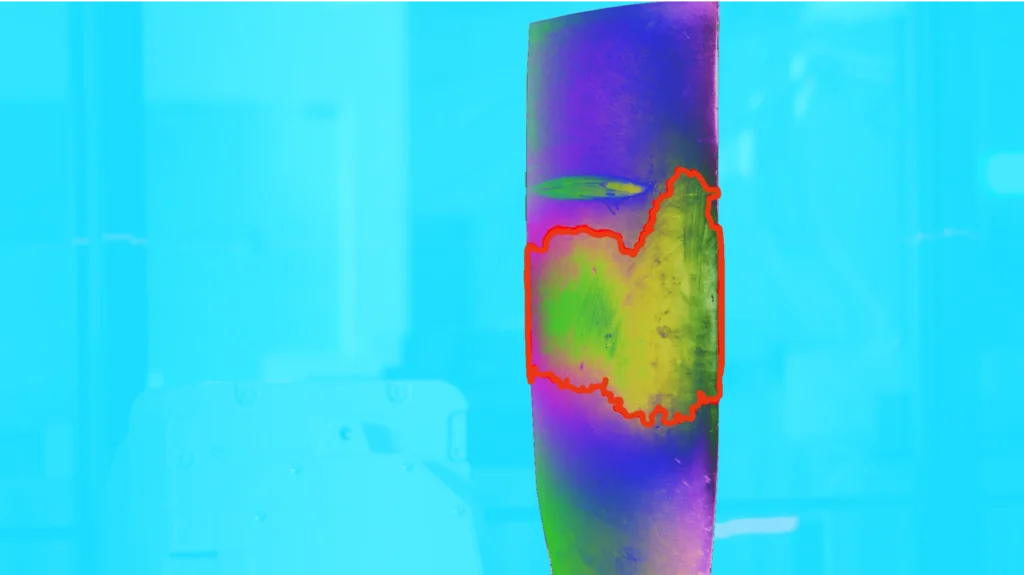

Visualize Spray Coverage

Preview programmed paths to evaluate spray coverage and refine settings before deployment, improving accuracy and simplifying complex spray tasks.

Closed-Loop Adaptive Spraying

Detect surface anomalies and generate optimized robot toolpaths for targeted treatments like material removal, with continuous inspection and verification to ensure precision and consistent quality.

Rapid Generation of Spray Paths with Easy Adjustment of Process Parameters

Visualize Spray Coverage

Closed-Loop Adaptive Spraying

Detect surface anomalies and generate optimized robotic toolpaths for targeted treatments like material removal, with continuous inspection and verification to ensure precision and consistent quality.

case study

Achieving Programming Precision

Programming circular counter bore movements manually, was previously unachievable, leading to inconsistent and unsatisfactory results. Augmentus streamlined the process, eliminating inefficiencies and enabling consistent, high-quality results that were unattainable with manual spraying.

Precise and Rapid Set-Up and 3D Reconstruction

- Integrates 3D scan or CAD data into workflows directly

- Captures complex geometries of different shapes and sizes

- Augmentus Vision ensures high accuracy manufacturing automation

Generate, Optimize, and Simulate Paths

- Automatically generates robot toolpaths

- Optimizes toolpaths to avoid kinematic challenges

- Run offline simulation to review motion, eliminating trial-and-error

Deploy, Inspect and Correct

- Augmentus is compatible with major robot OEMS, no coding required.

- Closed-Loop function enables adaptive automation for high-variability manufacturing

Gain Your Edge with Augmentus

Can Augmentus handle reflective or dark surfaces for 3D scanning?

Yes, Augmentus can accommodate reflective or dark surfaces in 3D scanning, though these surfaces can present unique challenges due to light absorption or reflection. Augmentus offers techniques and adjustments to enhance scan accuracy on these surfaces. For applications requiring high precision, we may recommend compatible scanners specifically designed to handle reflective or low-light surfaces, ensuring reliable and detailed scans.

Is it possible to integrate Augmentus with tools that use custom scripts?

Yes, Augmentus can be integrated with tools that use custom scripts. For custom script integration, users can leverage the solution’s customizable API settings to define unique actions, manage custom I/O configurations, and incorporate additional commands, ensuring that Augmentus fits smoothly into various operational setups.

How long does it take to install Augmentus on my existing robot?

Installing Augmentus on your existing robot is a straightforward process, designed for quick deployment. The software comes pre-installed, and the setup involves connecting the robot to the system, configuring the station, and calibrating the scanner if needed. The exact time required will depend on your specific robot model and integration requirements, but the process is significantly faster than traditional programming methods.

Can Augmentus adjust for slight positional shifts in the workpiece after setup? My current process involves manually placing the workpiece in the cell.

Yes, Augmentus can compensate for slight positional shifts in the workpiece after setup. Using in-situ correction and 3D scanning capabilities, Augmentus detects deviations in the workpiece’s position and adjusts the robot’s path accordingly. This feature is especially beneficial in setups where workpieces are manually placed, as it minimizes the need for precise placement and reduces manual adjustments, ensuring accurate and consistent processing.

How does Augmentus reduce my programming downtime?

Augmentus significantly reduces programming downtime by eliminating manual coding and automating complex path planning. Here’s how:

3D Scanning for Model Generation – If you don’t have CAD files, programming a robot can be time-consuming. Augmentus eliminates this bottleneck by integrating 3D scanning to create precise digital models of your workpieces. This removes the need for CAD files or manual measurements, streamlining path planning and reducing setup time.

AutoPath for Rapid Path Generation – Traditionally, defining tool paths requires extensive manual adjustments and expertise. Augmentus’ AutoPath feature automatically generates optimal paths based on your process requirements, significantly reducing programming time.

Path Optimizer for Error-Free Execution – Manually resolving singularities, reachability issues, and collision avoidance can take hours. Augmentus’ Path Optimizer detects and resolves these challenges automatically while maintaining consistent tool velocity, ensuring smooth and efficient motion without manual intervention.

Seamless Code Generation – Once the program is created, Augmentus automatically generates robot code that is compatible with major robot brands. This eliminates the need for extensive debugging and manual coding adjustments, allowing for quick deployment.

In-Situ Part Correction for Reduced Rework – Production deviations often require manual reprogramming. Augmentus’ in-situ part correction compensates for positional variations, reducing errors and the need for manual intervention.

By integrating these automation-driven features, Augmentus minimizes downtime, reduces reliance on skilled programmers, and accelerates your overall production workflow.

Need Expert Guidance Before Choosing?

Discuss your requirements with our automation experts to find the perfect fit.

See how it works in your Application

For welding that demands precise torch alignment and controlled speed to produce strong, defect-free welds across various joint types.