Insights Hub

Augmentus Awarded Most Innovative Solution at ABB Value Provider Awards

We are honored to receive the ABB Value Provider Award for Most Innovative Solution, recognizing our commitment to transforming manufacturing automation through our no-code AI robotics solution. This award affirms our mission to eliminate the complexity of robot programming, by empowering manufacturers to automate high-mix and high-variability production with unprecedented...

AutoPath™ by Augmentus: Automating A Deburring Process Without Manual Teach Pendant Programming

Deburring parts with complex geometries, such as wheel rims, is often a time‑intensive challenge for manufacturers seeking to automate the process. While it’s straightforward to program simple trajectories like straight lines or circles, non‑uniform curves and irregular shapes typically require extensive manual programming and tuning, which consumes valuable production time....

IMTEX Forming 2026 / 21-25 January

IMTEX Forming 2026 | January 21-25 | Bangalore International Exhibition Centre, Bengaluru, India Augmentus Robotics is proud to be part of IMTEX Forming 2026, demonstrating how our no-code solution, AutoPath™, resolves bottlenecks associated with traditional robot programming. The showcase is a joint effort between Augmentus and iTech Robotics & Automation....

Singapore Airshow 2026 / 3 to 6 Feb 2026

Augmentus at Singapore Airshow 2026 We're excited to be part of Singapore Airshow 2026, happening 3–6 February at Changi Exhibition Centre. Join our team to explore how no-code robotic automation is transforming the aerospace and MRO industries—from faster deployment to adaptive path planning that handles part variability with ease. Let’s...

iREX 2025 / 3 to 6 Dec 2025

Augmentus is excited to announce our participation in iREX Tokyo 2025, where we will be exhibiting together with Nanyo, one of Japan’s leading industrial automation partners. At this year’s exhibition, we will showcase our vision-guided robotic system, featuring auto path generation and no-code programming. Visitors will be able to see...

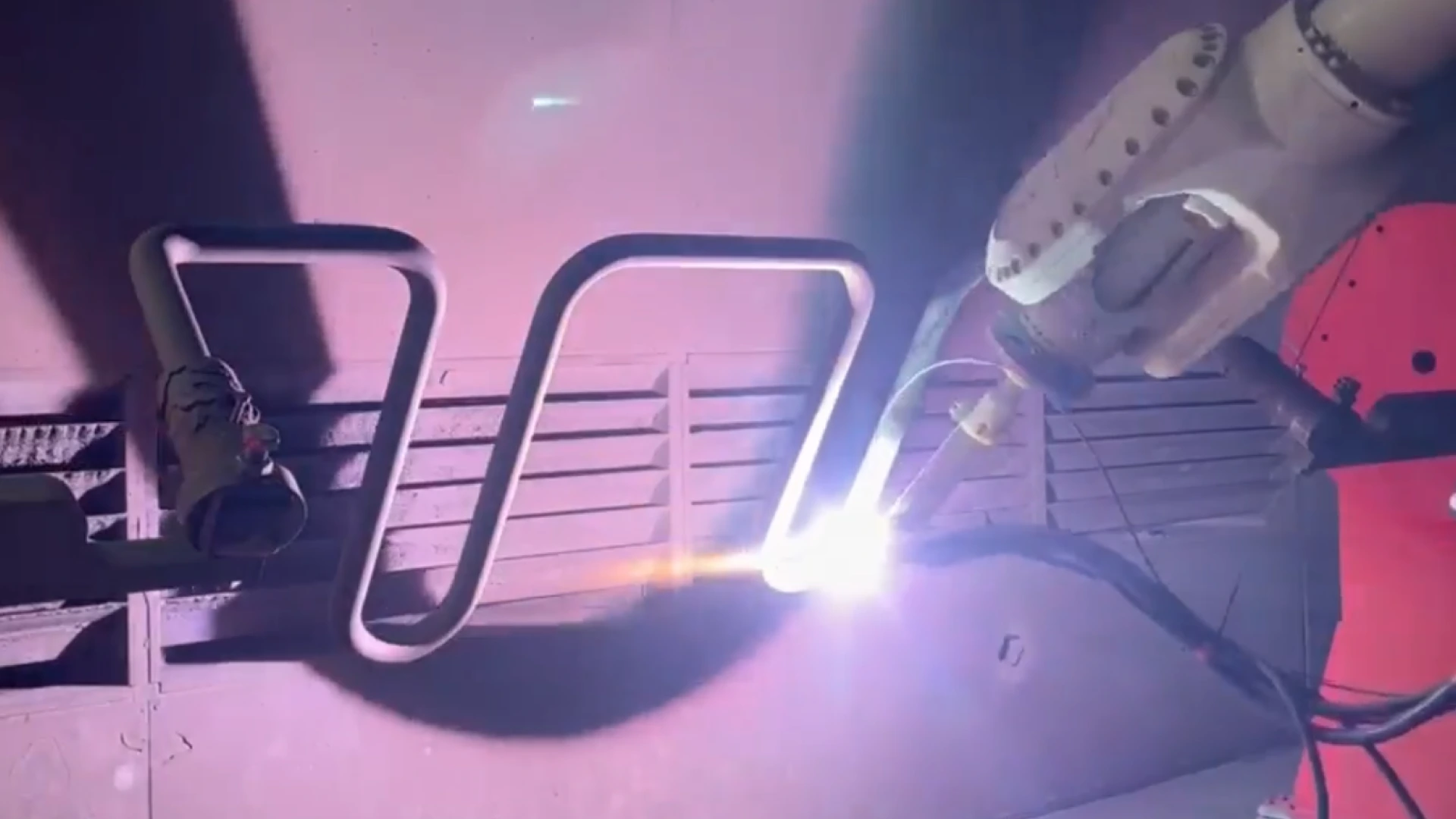

Automated Thermal Spraying for Bent Pipes: Faster Programming with AutoPath

Overview Thermal spraying of bent or curved pipes traditionally requires extensive robot programming to ensure correct spray angles, stand-off distances, and coating coverage. Each new pipe geometry can take days to program manually, often demanding high levels of robotics expertise. The result is long deployment times, costly trial-and-error, and inconsistent...

Autonomous Sandblasting for Aerospace MRO — How Augmentus Unlocks High-Mix, Rapid-Turnaround Operations

Industry Context Aerospace Maintenance, Repair, and Overhaul (MRO) companies face one of the most extreme forms of high-mix, high-variability manufacturing. Every aircraft component—engine housings, landing gear brackets, turbine blades, composite panels—arrives with different levels of wear, corrosion, and dimensional deviation. Sandblasting is one of the most critical yet time-consuming stages,...

Metalex Thailand 2025 / 19 to 22 Nov

It used to take 3-5 days to program a new SKU. Augmentus does it in less than 30 minutes. Want to see it in action? Visit us at METALEX—we’re partnering with Asmech Technology to show how Augmentus works with system integrators to deliver accurate and effective adaptive automation across various...

MTS Southwest 2025 / 4 to 6 Nov 2025

📍 We’re heading to MTS Southwest 2025 – Nov 4–6 at the Kay Bailey Hutchison Convention Center, Dallas TX! Discover how our adaptive robotic solutions are solving real-world manufacturing challenges, without the complexity. Augmentus Robotics’ Head of GTM (NA) Matt Jones will be speaking at Manufacturing Technology Series - Southwest...