Insights Hub

Augmentus Awarded Most Innovative Solution at ABB Value Provider Awards

We are honored to receive the ABB Value Provider Award for Most Innovative Solution, recognizing our commitment to transforming manufacturing automation through our no-code AI robotics solution. This award affirms our mission to eliminate the complexity of robot programming, by empowering manufacturers to automate high-mix and high-variability production with unprecedented...

AutoPath™ by Augmentus: Automating A Deburring Process Without Manual Teach Pendant Programming

Deburring parts with complex geometries, such as wheel rims, is often a time‑intensive challenge for manufacturers seeking to automate the process. While it’s straightforward to program simple trajectories like straight lines or circles, non‑uniform curves and irregular shapes typically require extensive manual programming and tuning, which consumes valuable production time....

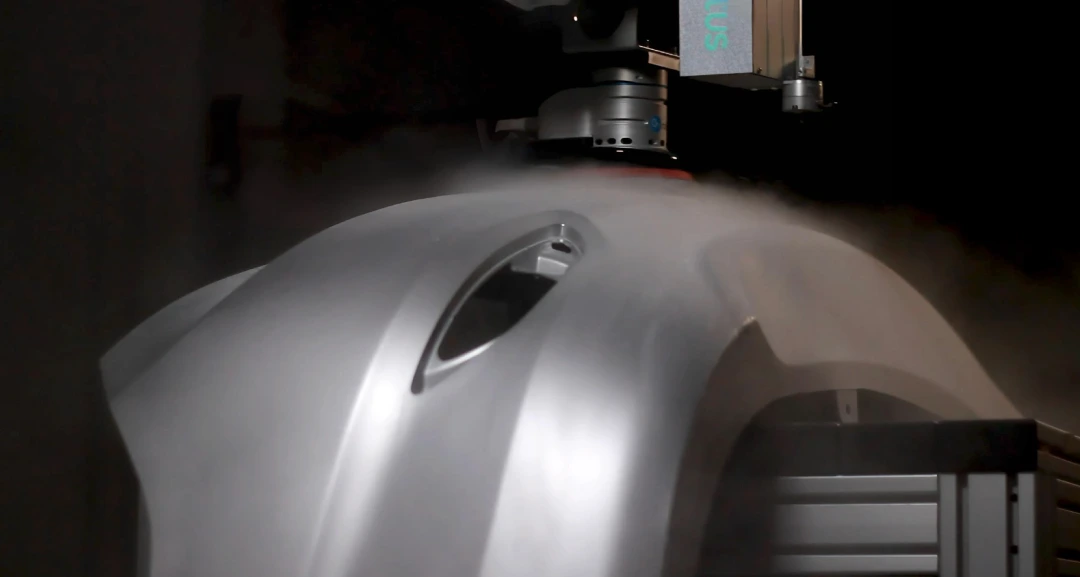

3D Scanning with Industrial Robots: Strategies to Maximize Part Reconstruction Accuracy

3D scanning in industrial automation isn’t just about hardware specs; it's also a critical part of accurate part reconstruction for robotic workflows. When deployed on industrial robots, the effectiveness of a scan is determined not solely by the tool in use, but by the scanning strategy employed. Geometry, size, complexity,...

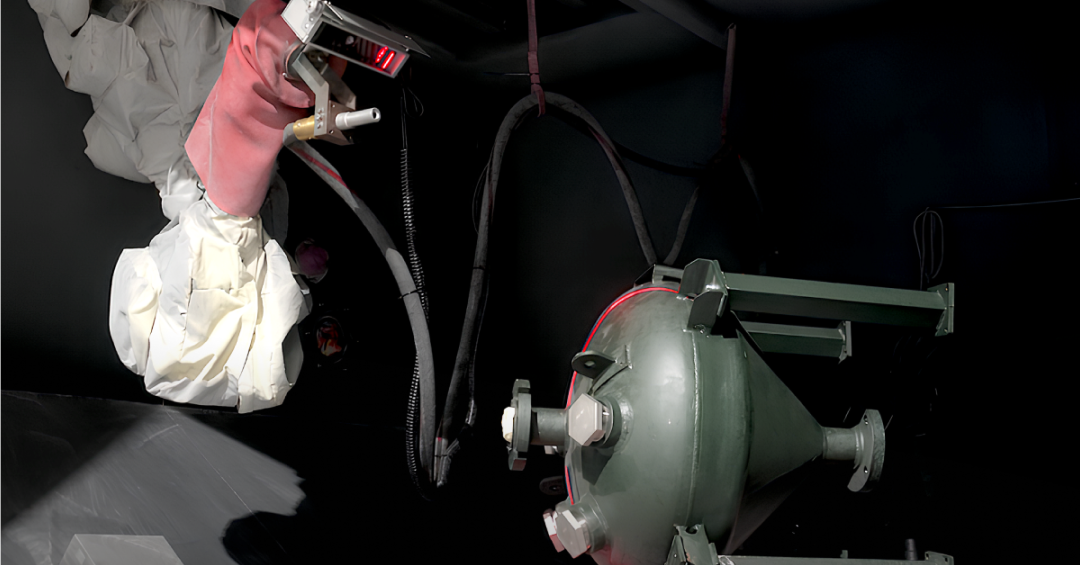

Programming Thermal Spray Robots: Comparing Teach Pendants, OLP, and Augmentus

Thermal spray applications, such as plasma spray, HVOF, HVAF, and arc spray coatings, play a vital role in aerospace, industrial equipment, and MRO (Maintenance, Repair, and Overhaul) processes, where precision and consistency are essential. Achieving the required coating uniformity, adhesion, and minimal overspray hinges on how well robots are programmed...

Yaskawa Motoman Robot Programming: How to Get Started

(Image Source: Yaskawa Motorman)They say programming industrial robots is only for seasoned professionals. But is it really? Yaskawa Motoman robots might just prove that wrong. With the right guidance, even the new ones to robotics can begin programming these powerful machines. In this guide, we’ll break down the essentials...

How to Spray Gel Coat on a Boat: A Step-by-Step Guide

Spraying gelcoat is a crucial step in maintaining and enhancing the appearance of a boat. As boating technology advances, the demand for high-quality finishes has never been higher. To achieve superior finishes, one needs to have the right preparation and tools and follow specific procedures.Be it restoring an older...

Surface Finishing: Process Types, Methods & Technologies

Surface finishing is critical to a product’s performance, appeal, and sales. Whether you’re producing consumer electronics or industrial machinery, the finishing process in manufacturing can make all the difference.Over 80% of product recalls in the automotive industry are due to surface defects. This shows the importance of effective surface finishing...

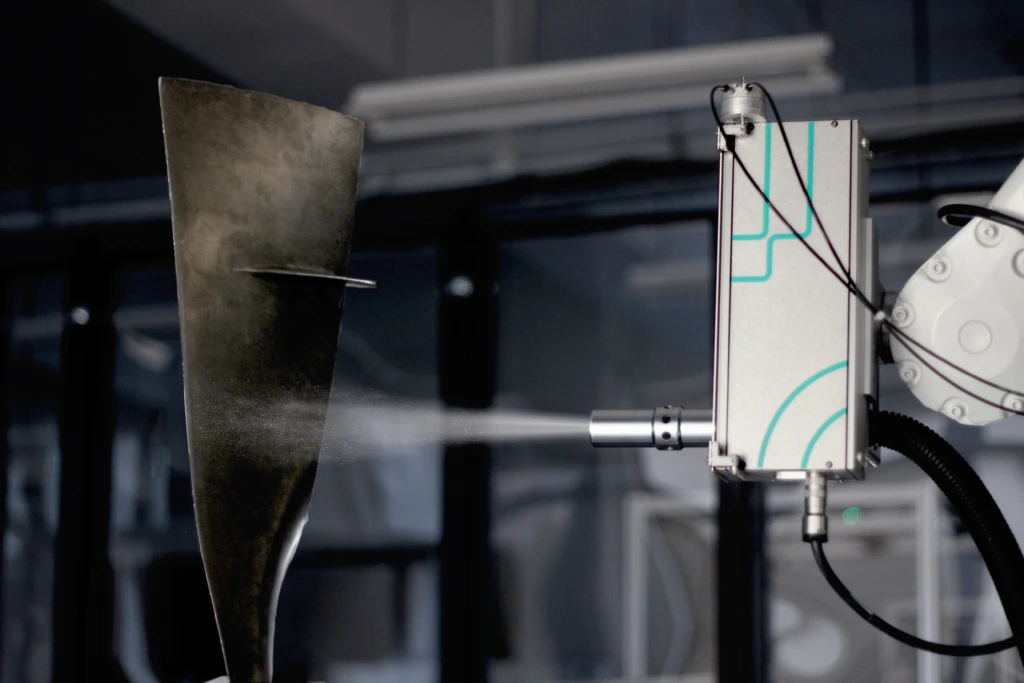

Blasting Automation and Robotics: How Robots Are Used in Sandblasting

Around the world, companies are increasing their use of robots. According to the International Federation of Robotics (IFR), the global average for industrial robots per 10,000 manufacturing workers has grown from 66 in 2015 to 126 in 2021. Robotics is a rapidly advancing field that promises significant improvement in cost-savings...

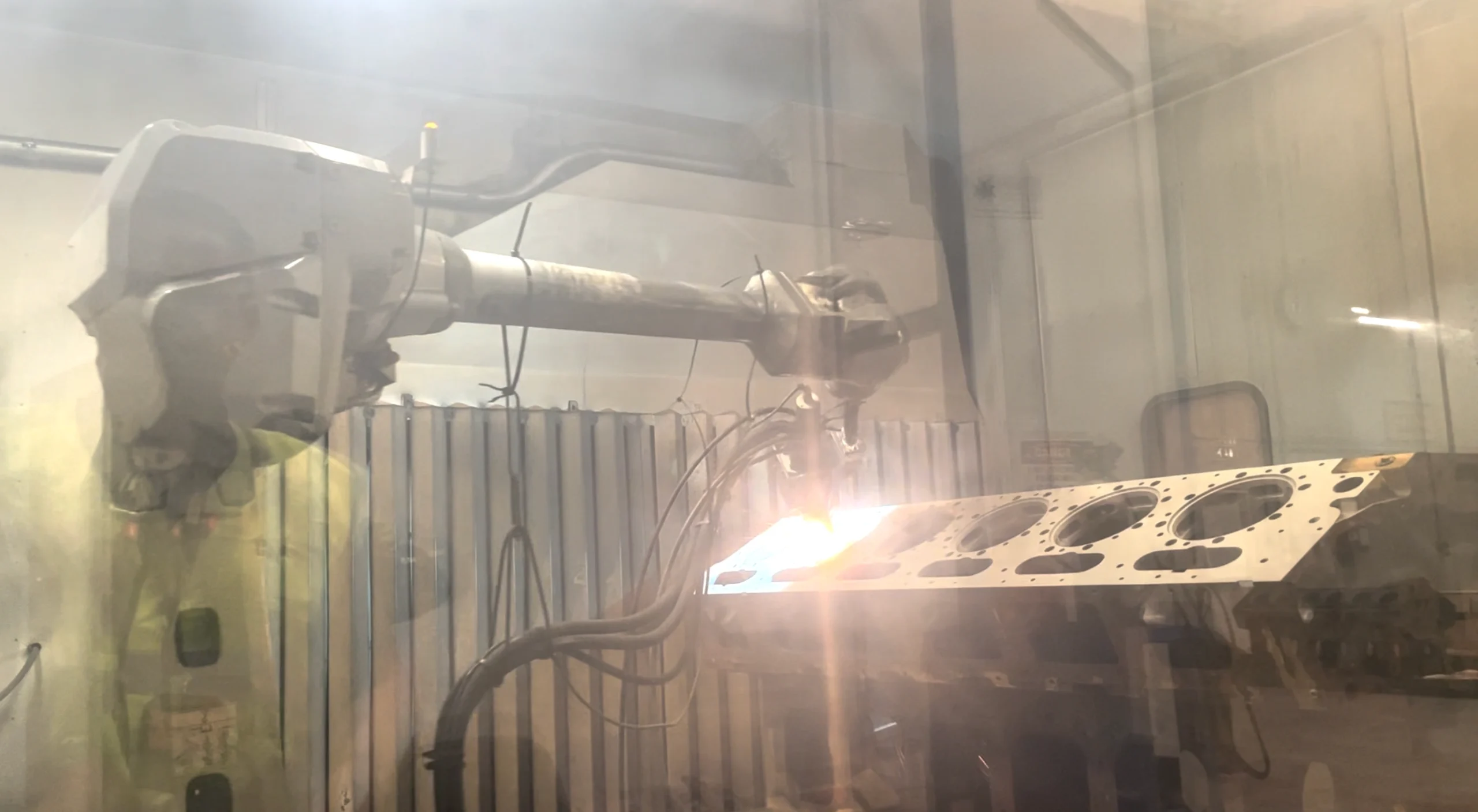

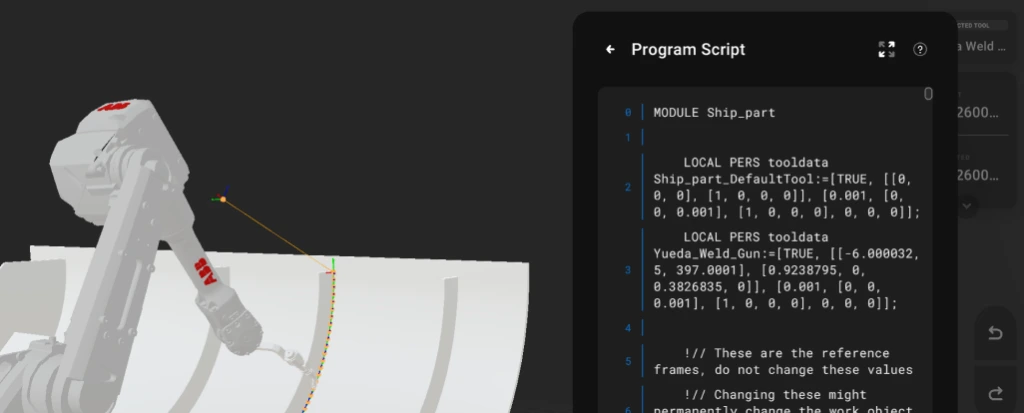

Mastering Robotic Welding Programming: A Comprehensive Guide

The industrial robotics market share is expected to reach $49.25 billion by 2030. It is predicted that programmers of robots will make a fortune out of this. Despite initial intimidation, especially in robotic welding programming, mastering this field can be very rewarding. With the right approach and tools, one can...