Insights Hub

The Right 3D Vision Scanner for Robotic Programming: Laser Profilers vs Structured Light Scanners in Industrial Automation

Key Takeaways In high-mix, high-precision manufacturing environments, selecting the appropriate 3D vision technology is critical to successful robotic automation and robot programming. This article compares laser profilers and structured light scanners, the two most prevalent types of 3D vision systems, to help manufacturers, system integrators, and automation engineers make informed...

ICSP 2025 / 22 to 25 Sep 2025

We're exhibiting at the International Conference on Shot Peening 2025! This edition is held at Purdue University in Indiana, US. The team will be meeting likeminded individuals to talk about the shared commitment to advance the field of surface treatment. Our CEO & Co-Founder, Daryl Lim, and Account Executive, Justin...

The True Cost of Teach Pendant Programming in a High-Mix Manufacturing Landscape

Introduction Industrial robots have transformed manufacturing by automating repetitive and hazardous tasks. For decades, teach pendant programming has been the default approach for setting up robot motion and logic. It is often perceived as cost-effective and straightforward. Yet as manufacturers face growing pressure to deliver more customized products at shorter...

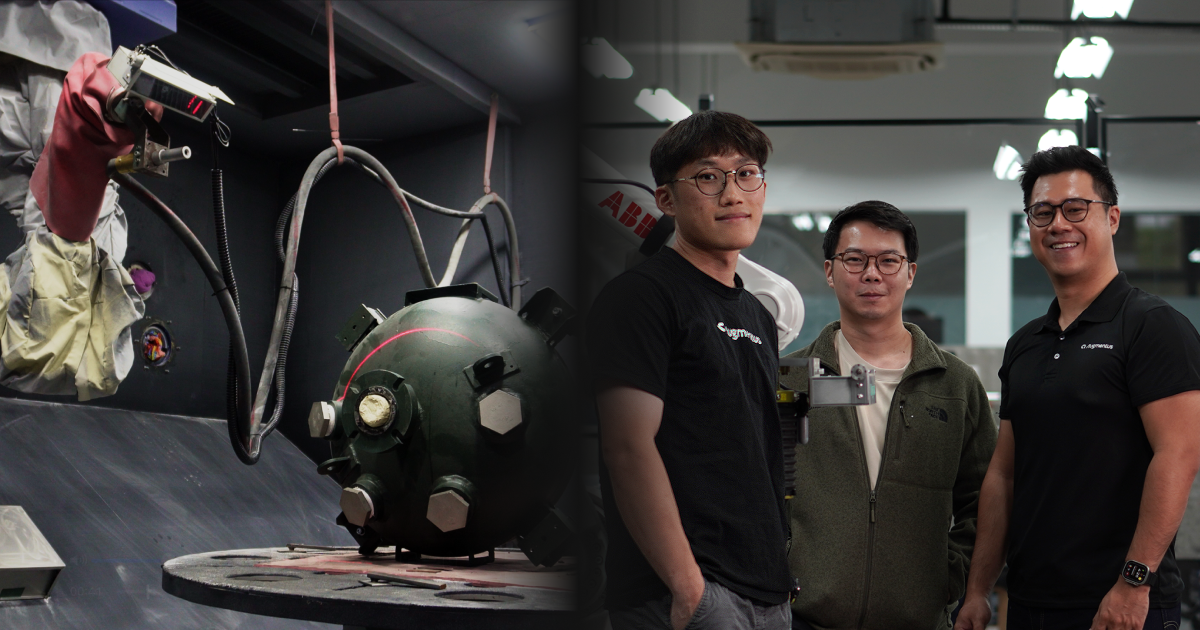

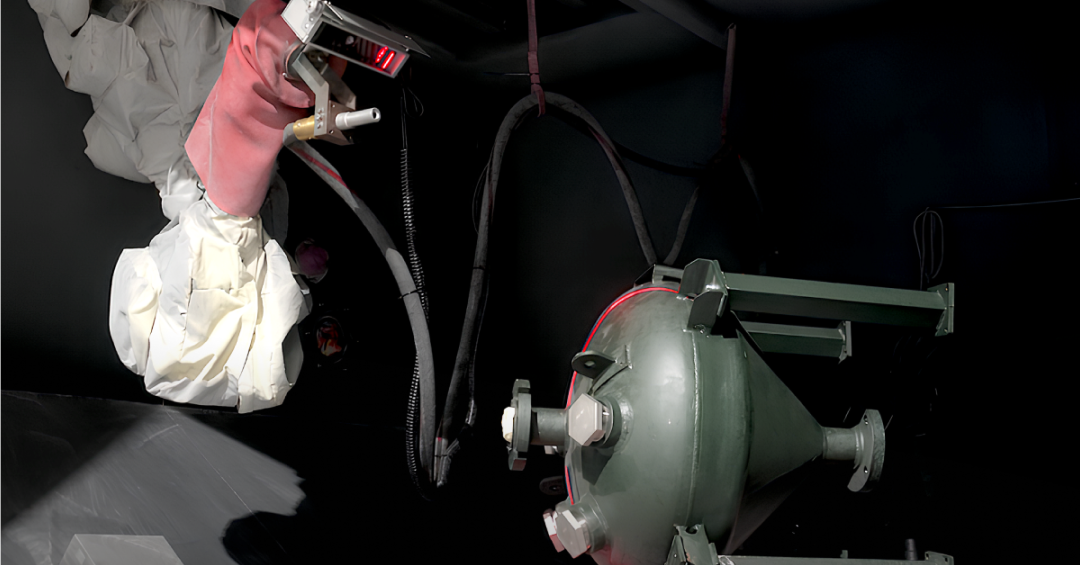

Building the Future of Scalable Automation: Augmentus x sentenso

Augmentus is proud to be a strategic partner of sentenso, a leading solution provider with deep expertise in shot peening and blasting. This collaboration brings together sentenso’s technical know-how in robotic shot peening and Augmentus’ hyper-adaptive, no-code automation platform to deliver turnkey solutions that are faster to deploy, easier to...

Augmentus Raises $11M to Scale Physical AI for High-Mix, Complex Robotic Surface Finishing and Welding

Singapore – [Jul 9, 2025] – Augmentus, the developer of an intelligent no-code robotics solution, announced today that it has raised USD $11 million (SGD $14 million) in a Series A+ funding round. The funds will be used to accelerate regional deployment of its fully autonomous robotic surface finishing and...

Cut, Weld, Finish: How Manufacturers are Automating Every Step of Fabrication

Why the Production Line Needs a Second Look Manufacturers today are caught between two seismic shifts. Rising labor cost[1][2] and labor shortages[3] continue to deepen, with an estimated 10 million vacancies in global manufacturing[4]. Simultaneously, market demand is pushing manufacturers toward greater product diversity and mass customization—the hallmark of high-mix,...

ITSC 2025 / 6 to 7 May 2025

We’re exhibiting at the International Thermal Spray Conference and Exposition (ITSC)! 📍 Booth 611 | Vancouver Convention Centre East 📅 May 6–7, 2025 Join us to experience our latest no-code adaptive robotic solution, built to streamline and automate complex surface finishing tasks. Stop by to meet the team and explore...

3D Scanning with Industrial Robots: Strategies to Maximize Part Reconstruction Accuracy

3D scanning in industrial automation isn’t just about hardware specs; it's also a critical part of accurate part reconstruction for robotic workflows. When deployed on industrial robots, the effectiveness of a scan is determined not solely by the tool in use, but by the scanning strategy employed. Geometry, size, complexity,...

Mastering External Axes: The Hidden Challenge in Robot Programming – And How to Solve It

The Challenge No One Talks About In industrial automation, external axes—like linear rails, turntables, and positioners—are a double-edged sword. They expand a robot’s reach, making it capable of handling larger, more complex workpieces. Yet, they introduce a major programming nightmare: synchronizing movements between the robot and external axes. For years,...