table of contents

- Heading 1

- Heading 1

- Heading 1

share this

Key Takeaways

In high-mix, high-precision manufacturing environments, selecting the appropriate 3D vision technology is critical to successful robotic automation and robot programming. This article compares laser profilers and structured light scanners, the two most prevalent types of 3D vision systems, to help manufacturers, system integrators, and automation engineers make informed decisions.

Introduction: The Role of 3D Vision in Modern Robotics

Robots today are expected to handle increasingly complex and varied tasks. In industries ranging from aerospace to automotive, and a range of processes from surface finishing to welding, the ability to adapt to part variability and environmental challenges is critical.

Traditional robotic programming falls short in such scenarios due to the static nature of hard-coded paths, and a reliance on jigs and fixtures. 3D vision systems solve this by allowing robots to perceive and adapt to their environments.

However, not all vision systems are created equal—and the choice between laser profilers and structured light scanners can significantly impact the efficiency and accuracy of the automation process.

Laser Profilers in Robot Programming

Laser profilers are line-scanning devices that project a laser stripe onto the target surface. A receiver mounted at a fixed triangulation angle records how this stripe deforms across the part’s geometry. By moving either the sensor or the workpiece, a full 3D point cloud can be reconstructed from these sequential profiles.

Laser profilers are particularly effective when mounted on robotic arms—full scan coverage is possible with the additional axes of movement provided by the robot.

A laser scanner is being used as part of an Augmentus demonstration for robotic sandblasting processes. (YouTube)

A laser scanner is being used as part of an Augmentus demonstration for robotic sandblasting processes. (YouTube)

Advantages of Laser Profilers

- High Resolution & Precision: Achieves single-digit micron resolution, making it ideal for capturing extremely fine details.

- Long-Range Capability: Can scan over extended distances while maintaining accuracy, making them suitable for large parts and expansive industrial setups.

- Resilient to Lighting Variations: Less affected by ambient light, eliminating the need to adjust environmental conditions.

- Handles Complex Surfaces: Effective in scanning intricate contours and textured geometries.

Limitations of Laser Profilers

- Line-by-Line Scanning: Captures one profile at a time, so wide surface areas require longer motion sequences.

- Sensitivity to Motion: Since scanning occurs during movement, vibrations can introduce noise into the data. Overly slow scanning motion can also capture more data than is required, unnecessarily extending processing times.

- Requires More Coordination: Deformed or skewed scans can occur if the scan speed and robot arm speed are not aligned.

Structured Light Scanners in Robot Programming

Structured light systems project coded light patterns (grids, sinusoidal stripes, or speckle fields) onto an object and record how these patterns deform. Using photogrammetry and triangulation, the full 3D shape can be reconstructed in one or a few exposures.

These scanners excel at capturing complete, high-resolution surface geometry quickly in controlled conditions. They are often used for offline inspection, metrology, and reverse engineering—where static parts can be scanned at once without motion.

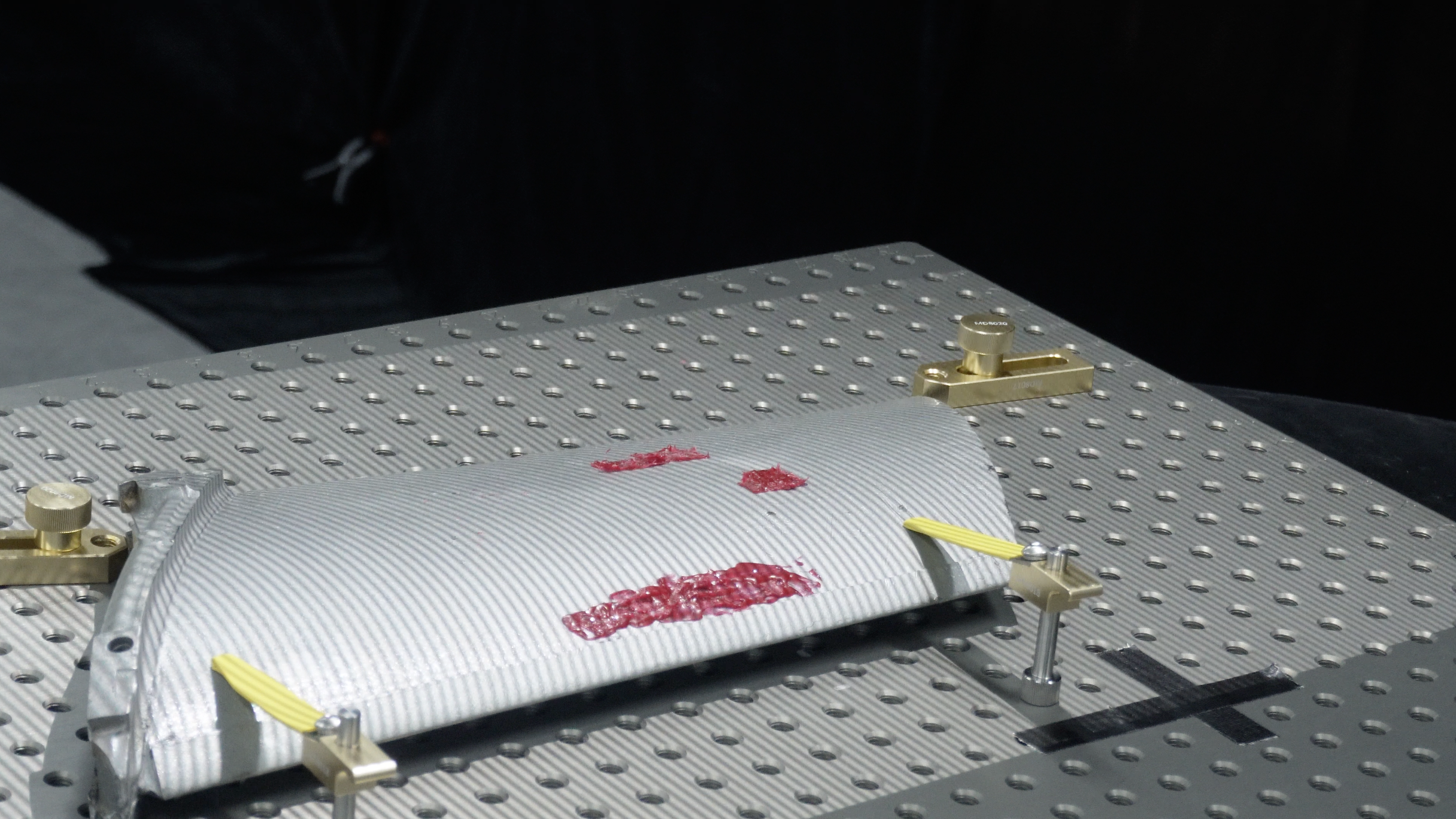

A structured light scanner in use, attached to a robot arm.

A close-up photograph of the grid lines used to capture part geometry.

Advantages of Structured Light Scanners

- Full-Field Capture: Able to reconstruct an entire object in a single shot, reducing the number of scan passes required.

- Fast Acquisition in Static Scenarios: Efficient when the part is stationary, such as in QA labs or pre-production design.

Limitations of Structured Light Scanners

- Sensitivity to Environment: Performance degrades in high-glare, dusty, or high-vibration shopfloors.

- Static Object Requirement: Not suitable for real-time scanning while robots or parts are moving.

- Lighting Dependence: Strong ambient light can interfere with the projected patterns, reducing accuracy.

- Resolution: Compared to results from a laser profiler, scans generated from structured light have lower resolutions due to current hardware constraints.

How Augmentus Selects the Right 3D Vision Hardware

- Part Size

- Large components are best handled by laser profilers, which maintain accuracy over extended ranges.

- Smaller parts can be efficiently scanned with structured light, as they can capture fine details in a single shot.

- Quick Cycle Time

- For applications where fast acquisition is critical, structured light is preferred since it captures full-field data in fewer cycles.

- Outdoor Environment

- Outdoor or shopfloor settings with variable lighting or vibration are better suited for laser profilers, which are less sensitive to environmental noise.

- High Resolution/Details in the workpiece

- When the task demands detection of fine details, laser profilers deliver superior precision.

- Cell Space Constraints

- In setups with a limited robot footprint, structured light offers an advantage since it can scan more efficiently from a fixed position.

Automated Mesh Processing: The True Meaning of Scan To Path

One of the biggest challenges in 3D vision workflows is not the scan itself, but what comes after. Most conventional systems output raw point clouds that require manual stitching, mesh reconstruction, and format conversions before they can be used for robot programming. These steps are not only time-consuming but also introduce opportunities for error and data loss.

Augmentus addresses this with a proprietary vision processing engine that fully automates the transition from scan to mesh. Laser profiles or structured light frames are stitched into a unified digital representation, with automatic point cloud-to-mesh conversion built into the pipeline. This eliminates the need for external software, manual preprocessing, or operator intervention.

By removing these bottlenecks, manufacturers achieve a streamlined “scan–plan–deploy” workflow—where the robot moves directly from capturing a scan to executing an optimized toolpath. This is especially valuable in high-mix production, where reducing setup time and minimizing manual steps is critical to achieving consistent and scalable automation.

Because the process is designed to be plug-and-play, the reliance on deep technical expertise is greatly reduced. Operators can run the workflow with minimal training, making advanced automation accessible on the shop floor.

Conclusion

The comparison between laser profilers and structured light scanners highlights that each has unique advantages depending on the task and environment. Laser profilers are indispensable for dynamic shopfloor operations where robustness and precision are critical, while structured light scanners shine in processes that prioritize efficiency and speed.

Yet, the true enabler of scalable robotic automation lies not only in the scanning hardware but in how the captured data is transformed into actionable motion. With automated mesh processing, manufacturers no longer face delays from manual conversion or stitching—scans translate seamlessly into optimized robot paths. This integration ensures that whether using a profiler or structured light, the workflow remains efficient, reliable, and operator-friendly.

By combining flexible vision technology with automated processing, manufacturers and system integrators can shorten deployment cycles, reduce reliance on fixtures, and achieve the adaptability needed for high-mix, high-precision production. This approach makes robotic automation not just feasible, but resilient and future-ready.

Contact Augmentus or request a demo to get started, or see how we use 3D scans to simplify the robotic automation process for manufacturers. Read More