table of contents

- Heading 1

- Heading 1

- Heading 1

share this

Introduction

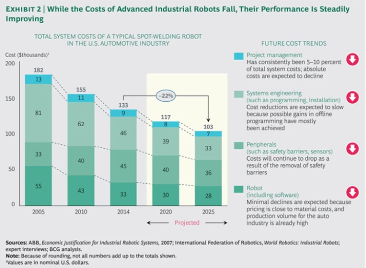

The increased capabilities of robots, coupled with their falling costs, has resulted in higher rates of automation in manufacturing processes such as welding. Robots are traditionally programmed to perform the exact same motion for every workpiece. Unfortunately, each workpiece may have dimensional and positional variations or even defects.

Because of these limitations in traditional programming, manufacturers often end up with flawed workpieces, imperfect welds, and costs incurred in rework, wastage, and scrapping.

Figure 1: Decreasing costs of robots despite their performance steadily improving[1]

To resolve the issue, seam finding and seam tracking are used in automated welding processes to minimize errors, improve weld quality and increase efficiency. But what is seam finding and seam tracking? What are their differences? And how are they conducted in an industrial setting? This whitepaper aims to serve as a cost-and-benefit analysis of the respective processes.

Seam Finding

What is Seam Finding?

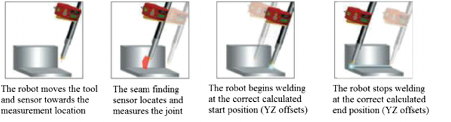

Also known as weld position finding, seam finding is a pre-weld process, of which the working principle is to:

- Detect weld feature points—distinctive coordinates or points of interest on a weld seam, such as corners or edges.

- Identify deviations between the detected feature point position and the saved, original feature point position

- Perform position compensations and corrections based on the deviation

In short, seam finding precisely locates the weld joint and adjusts the robot’s program to ensure that welds are applied at the correct position.

Figure 2: Example of a seam finding process[2]

Seam finding methods

There are various ways to find a seam, but these methods can generally be categorized as either tactile or visual.

Tactile

Touch/nozzle sensing[3]

Process

- Touch sensing uses a low voltage to detect the conductive surface of the intended workpiece, often via a weld wire fed from the end of the torch.

- The orientation of the part is determined when the wire touches the conductive surface, which completes a circuit/ triggers an electric short This method may vary across different systems.

Figure 3: Diagram illustrating touch sensing[4]

- The science of nozzle sensing is similar: Instead of a wire, the nozzle itself is used to complete the circuit.

Figure 4: Nozzle Sensing Image[5]

| Pros | Cons |

| Low complexity; Built-in pendant commands | Requires a wire cutter/wire brake (optional) |

| Works on all conductive material | Limited to lap joint thickness (>3 mm) |

| Easy to teach with macro jobs | Slower vs. laser or camera |

| Does not interfere with joint access | Limited ability to detect joint gap |

| No external hardware is required on robot | Cannot find square butt joints |

| Performs multiple searches with one wire cut | |

| Locates most lap and fillet joint types; can also be used with V butt joints | |

| Offers a lower cost option

|

Wire Sensing[6]

Process

- This method uses a servo motor in the torch to quickly move the wire up and down while the robot moves across the part.

- This allows material height and gaps to be measured as well.

| Pros | Cons |

| Can detect joints like butt joints that cannot be easily found using traditional static wire or nozzle touch sense | Requires specific hardware and software licenses |

| Can be used for lap joints less than 3 mm | Slower than visual techniques |

| Can detect joints like butt joints that cannot be easily found using traditional static wire or nozzle touch sense | Not available on all brands of welding power supplies |

Visual

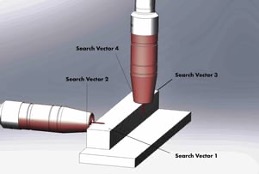

Laser Sensor Seam Finding[7]

Process

- Laser scans are able to pick up multiple characteristics in a single scan

- There are 1D, 2D, and 3D lasers.[8] With more dimensions, more characteristics can be captured, but the costs and technical complexity of the application increase in tandem as well

| Pros | Cons |

| Works on different materials in all lighting | Medium- to high-complexity; Training on vision system suggested |

| Easy to teach with macro jobs | May restrict access into part/tooling |

| Provides joint gap data | Limited field of vision may require multiple searches for large offsets |

| Long focal length; mount away from arc | |

| Locates 2.5D; offset and depth | |

| Compact and self-contained | |

| I/O interface can be retrofit to older controls |

Figure 5: Laser Sensor Seam Finding[9]

Seam Tracking

What is seam tracking?

While seam finding is a pre-weld process, seam tracking occurs during welding and is used to correct for weld seam deviations, which could arise due to[10]

- Environmental changes: temperature fluctuations or vibrations during welding may shift the seam position

- Fixture issues: if workpiece fixtures are unstable or inaccurately positioned, slight shifts during welding can result in seam deviation

- Robot precision: Limitations in precision movement mean that repeated operations, complex weld paths, or poor calibration may lead to minor errors over time.

To account for these deviations, seam trackers detect upcoming seam positions in order to dynamically adjust the robot path in real time.

Seam tracking methods

There are 3 broad methods used to track seams: tactile, through arc, and laser sensor.

Tactile Seam Tracking

Process

- This method uses a contact probe positioned a few centimetres in front of the arc. This probe physically touches the seam during welding.

- Based on the probe’s detected deviations, dynamic adjustments are made to the robot’s toolpath

Figure 6: Contact probe (grey piece on right) tracks the seam in front of the arc[11]

| Pros | Cons |

| Simple, durable, cheap | Physical wear of probe, which requires replacement or maintenance |

| Immune to arc light, reflections or electrical noise | Can cause marks or scratch sensitive parts |

| Works in harsh environments | Cannot handle complex or variable joint geometries |

| Reliable for straightforward seam types | Slower response than other systems, which limits high-speed welding |

| Able to be used on many types of material |

Through-the-Arc Seam Tracking (TAST)

Process

- TAST monitors the welding power supply to actively measure arc characteristics during welding, e.g. voltage

- Deviations in the seam will change the tip-to-work distance, resulting in a deviation in voltage.

- These deviations are translated to physical positions, which are accounted for by adjusting the robot’s path.

![]()

Figure 7: Diagram on how TAST corrects for deviation

| Pros | Cons |

| Low complexity | Requires weaving for 2 axes tracking |

| Reliable sensor and easy to support | Accuracy limited by arc/weld physics, this includes arc stability, conductivity |

| Immune to reflection, smoke, dust etc. | Requires a pre-weld search to find the weld joint |

| Simple integration | Cannot track ahead of weld as it only reacts after the deviation occurs |

| Offers a lower cost option | Thicker material needed |

Laser/ Camera Seam Tracking

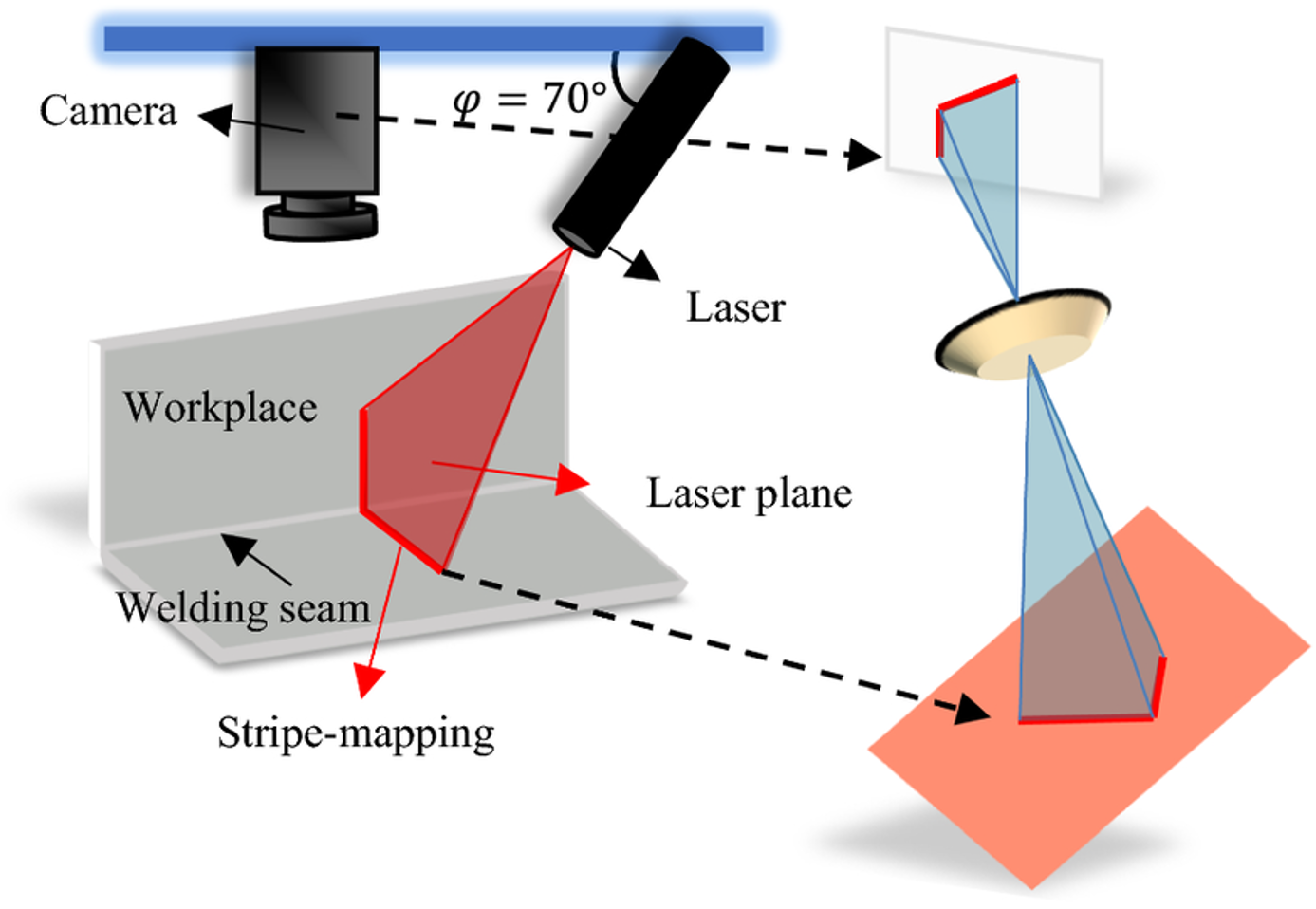

Process

- During welding, a laser is projected across the seam, and a sensor detects the reflected beams. Any deviation in the seam causes the laser to be reflected differently.

- The reflected laser captures a 3D model of the weld, including these deviations. This model is then used to adjust robot toolpaths

- High-speed cameras can be used to visualize the seam as well, identifying deviations by stitching images of the seam together

![]()

Figure 8: Laser seam tracking diagram[12]

| Pros | Cons |

| Low complexity | Requires weaving and thicker material |

| Reliable sensor and easy to support | Accuracy limited by arc/weld physics, this includes arc stability, conductivity |

| Immune to reflection, smoke, dust etc. | Requires a pre-weld search to find the weld joint |

| Simple integration | Cannot account for any deviations that occur between the point of time where the scan is taken, and the point of time when the seam is welded |

| Offers a lower cost option |

Conclusion

Seam finding and seam tracking are complementary technologies that together enhance reliability and efficiency of automated welding. Seam finding ensures that the process starts at the correct position, while seam tracking guarantees accuracy throughout the weld. Their integration minimizes rework, reduces scrap, and enables consistent, high-quality results.

The choice of seam tracking and finding depends on the balance between cost, accuracy, and environmental conditions. Commercial case studies show measurable business impact: reduced setup times, improved throughput, and near elimination of rework, proving that seam finding and tracking methods do help make the world of automated welding possible.

In summary, seam finding and seam tracking are no longer optional add-ons but core enablers of intelligent, autonomous welding systems that meet the demands of modern industry and gives manufacturers a competitive advantage over their competitors.

[1] Zinser, M., Rose, J. & Sirkin, H., 2015. How robots will redefine competitiveness. Boston Consulting Group, 23 September. Available at: https://www.bcg.com/publications/2015/lean-manufacturing-innovation-robots-redefine-competitiveness [Accessed 5 September 2025].

[2] Robotic arc welding sensors and programming in industrial applications – Scientific Figure on ResearchGate. Available from: https://www.researchgate.net/figure/Comparison-between-laser-vision-and-tactile-sensing-system-for-seam-finding-and-welding_fig8_282540974 [accessed 5 Sept 2025]

[3] Yaskawa Motoman. (2022) Pros and Cons of Robotic Seam Finding and Seam Tracking, Y-Blog, 31 March. Available at: https://www.motoman.com/en-us/about/blog/pros-and-cons-of-robotic-seam-finding-and-seam-tra (Accessed: 5 September 2025).

[4] Huber, S. (2020) Weld Joint Finding Methods Explained, ABIBLOG (Binzel – Abicor), 3 September. Available at: https://blog.binzel-abicor.com/usa/weld-joint-finding-methods-explained

(Accessed: 8 September 2025).

[5] Huber, S. (2020) Weld Joint Finding Methods Explained, ABIBLOG (Binzel – Abicor), 3 September. Available at: https://blog.binzel-abicor.com/usa/weld-joint-finding-methods-explained

(Accessed: 8 September 2025).

[6] Yaskawa Motoman. (2022) Pros and Cons of Robotic Seam Finding and Seam Tracking, Y-Blog, 31 March. Available at: https://www.motoman.com/en-us/about/blog/pros-and-cons-of-robotic-seam-finding-and-seam-tra (Accessed: 5 September 2025).

[7] Yaskawa Motoman. (2022) Pros and Cons of Robotic Seam Finding and Seam Tracking, Y-Blog, 31 March. Available at: https://www.motoman.com/en-us/about/blog/pros-and-cons-of-robotic-seam-finding-and-seam-tra (Accessed: 5 September 2025).

[8] Huber, S. (2020) Weld Joint Finding Methods Explained, ABIBLOG (Binzel-Abicor USA), 3 September. Available at: https://blog.binzel-abicor.com/usa/weld-joint-finding-methods-explained (Accessed: 8 September 2025).

[9] A weld feature points detection method based on improved YOLO for welding robots in strong noise environment – Scientific Figure on ResearchGate. Available from: https://www.researchgate.net/figure/The-basic-principle-of-laser-vision-sensor_fig3_365756689 [accessed 8 Sept 2025]

[10] ATINY Laser Sensor. (2024) How to Prevent Weld Seam Deviation in Welding Robots, ATINY Laser Sensor Blog, 29 October. Available at: https://www.atiny-lasersensor.com/article/how-to-prevent-weld-seam-deviation-in-welding-robots.html (Accessed: 8 September 2025).

[11] Tactile Seam Tracking for Column and Boom Welding Manipulator. (n.d.) Tactile Seam Tracking for Column and Boom Welding Manipulator, YouTube video. Available at: https://youtu.be/E9b4WmU6v34 (Accessed: 8 September 2025).

[12] Bancroft Engineering. (2025) Selecting the Right Seam Tracking Solution, Bancroft Engineering Blog. Available at: https://bancrofteng.com/selecting-right-seam-tracking-solution/

(Accessed: 8 September 2025).