table of contents

- Heading 1

- Heading 1

- Heading 1

share this

Augmentus is proud to be a strategic partner of sentenso, a leading solution provider with deep expertise in shot peening and blasting. This collaboration brings together sentenso’s technical know-how in robotic shot peening and Augmentus’ hyper-adaptive, no-code automation platform to deliver turnkey solutions that are faster to deploy, easier to operate, and built for variable part production.

“Augmentus’ 3D scanning and AI-powered path planning technology complement our expertise in shot peening, resulting in systems that are easier to deploy, faster to set up, and capable of handling a wide variety of parts with confidence.”

— Volker Schneidau, Managing Director, sentenso GmbH

Fig. 1 An Augmentus scanner is attached to a robotic arm as the robot scans and simulates the toolpath, as part of a demonstration.

Fig. 2 A complex sample part is scanned, creating a 1:1 model of the part within Augmentus’ virtual environment. This allows for Offline Programming (OLP) to take place, where the toolpaths can be optimized without having to stop existing production.

Augmentus As An Industrial Force Multiplier

This partnership was formed out of a shared vision: to simplify and accelerate automation adoption for complex, high mix manufacturing.

Because part geometries and treatment areas can vary widely, traditional robot programming for shot peening can be painstakingly slow and complex.

- Shot peening specialists do not always have robot programming expertise

- Multiple engineers are required during deployment, stationed for weeks on end

- Part variability requires manual reprogramming of the robots, which brings production to a standstill for re-teaching and testing, even for minor changes.

- Robot programming typically requires specialized languages like FANUC TP or ABB RAPID—yet experts in even one of these are scarce. Those fluent across multiple robot languages are even rarer.

All these issues combine to create undesirable opportunity costs for both sentenso and their end customers. The team recognized a need for more adaptable, less resource-intensive robot programming.

Why sentenso?

sentenso GmbH brings decades of expertise in designing robotic systems tailored for demanding production environments, with stellar track records in surface finishing, particularly with robotic shot peening. This partnership allows Augmentus to deliver localized support through proven turnkey systems, as we look to expand into the European Union (EU).

Shared Value, Scalable Impact

For Augmentus, partnering with ASIs (Authorized System Integrators) like sentenso enables us to extend our reach into specialized applications and offer end-users complete, turnkey systems via trusted local experts.

With the Augmentus system integrated, sentenso clients can now expect:

- Drastically Reduced Programming Time – Toolpaths for complex 3D geometries are generated automatically.

- Pre-Deployment Visualization – Simulate parts and processes in a 3D environment before deployment, reducing downtime and eliminating costly trial-and-error programming, collisions, and errors during production.

- Support for High-Mix, Low-Volume Workflows – Adaptive automation means less manual reprogramming when parts change. Offline Programming (OLP) allows you to program new parts while your production line continues to operate.

- Consistent Treatment Quality – Augmentus ensures smooth, precise motion even on non-uniform surfaces.

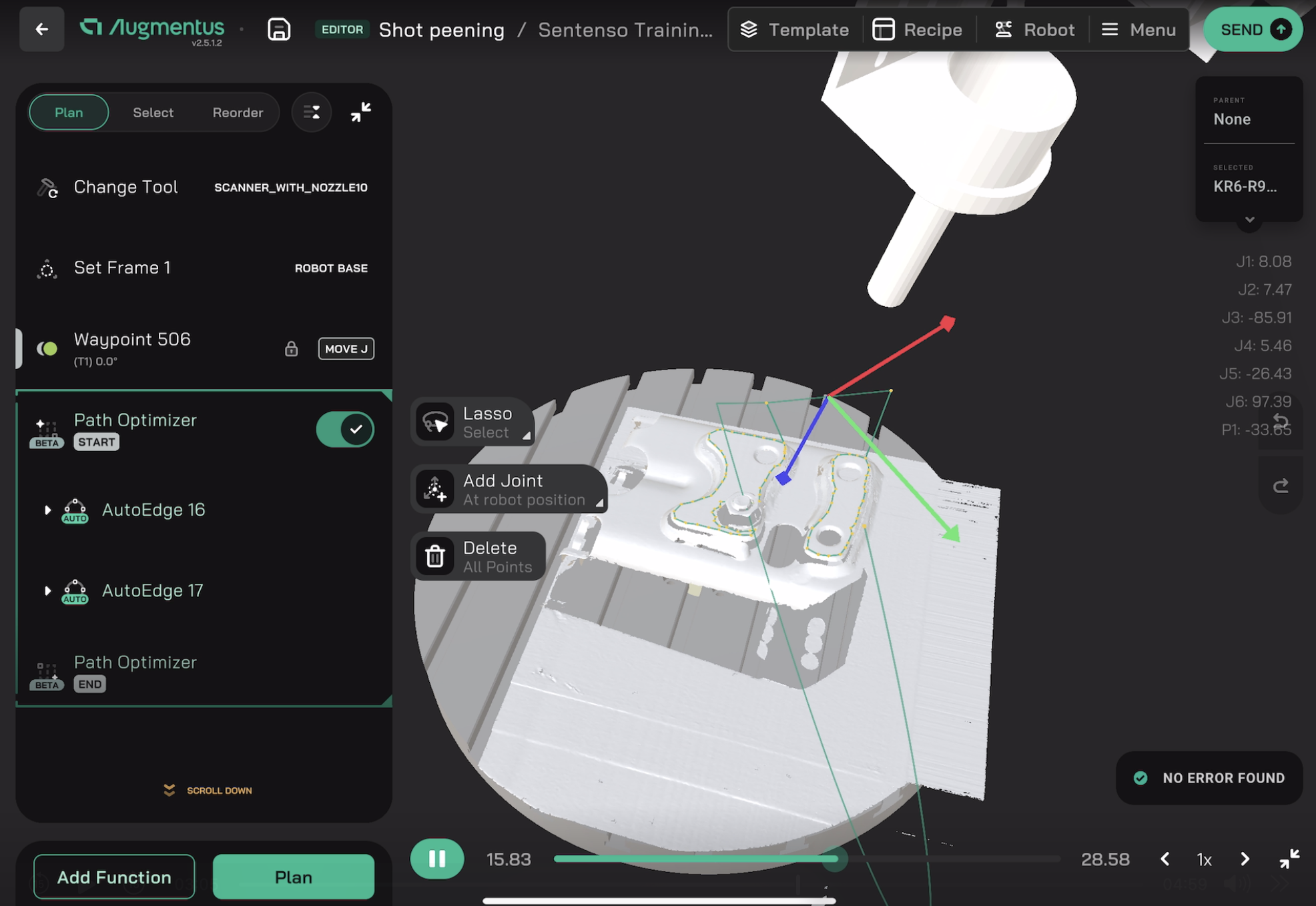

Fig. 3 A user interface view of Augmentus’ Path Optimizer in action. Unlike traditional teach pendant programming, this virtual model allows users to view and correct real toolpaths and simulate processes. Individual parameters such as angle of attack and velocity can also be specified, while alerting operators to potential equipment collisions.

This reduces project costs and accelerates ROI, while keeping operations resilient and adaptable.

How Augmentus Works With System Integrators

Our technology is robot-agnostic and integration-ready, allowing system integrators to focus on what they do best—designing and building customized solutions. In return, we provide valuable referral opportunities, technical support, and a software stack that gives our partners a competitive edge in high-mix industrial automation.

Click here to find out more about Augmentus’ system integrators.

Get in Touch with sentenso

For manufacturers looking to modernize their shot peening operations with scalable automation, we strongly recommend reaching out to sentenso. With Augmentus technology embedded, they deliver not just systems, but solutions built for tomorrow’s challenges.

👉 Contact sentenso today at info@sentenso.de to explore how this joint solution can work for your facility.