table of contents

- Heading 1

- Heading 1

- Heading 1

share this

All robots require specific programming that may seem daunting, especially for someone without a tech background. With investments from venture firms and the global robotics technology reaching 170.08 billion by 2027 [1], there will be a surge in demand for robot programmers in the coming years. This guide serves as an introduction to the types of robot programming methods in the industry and seeks advice on how to program your robot.

Robot Programming Methods: Top 3 Types

Robot programming has come a long way from coding instructions in a low-level language to high-level languages that have made it easy for end-users. These are the top 3 types of robot programming methods that are being used in the industry today.

1. The Teach Pendant

The most popular method of robot programming is the teach pendant, where over 90% of industrial robots are programmed using this method. The device comes with different buttons and a display to key in command inputs and edits the robot’s commands. It also has a large red button, which acts as an emergency button that stops robot operation immediately should a malfunction occurs, ensuring workers’ safety. A professional robot engineer or operator is needed to program a robot from point to point. They would have to use the buttons on the pendant to move it around and save each position individually. Once the robot motion has been programmed, the robot can play back the points at full speed.

ABB teach pendant. Image by ABB

Advantages

- Precision: Robots are programmed digitally using numerical coordinates, providing precise positioning.

- Industry Standard: Most industrial robots come with a teach pendant, which many technicians would be familiar with.

Disadvantages

- Requires technical expertise: The learning curve for this method is extremely high; different robot brands require a particular programming language. A lot of training is also needed to learn how to program a robot. It might be difficult for people who are unfamiliar with programming to learn.

- Time-consuming: As this is a form of online programming, the robot must be put into “teach mode”, adding to the total time taken to program the robot. It is disruptive to the whole system due to robot downtime.

2. Teaching by Demonstration

Also known as lead-through programming, this method involves physically moving the robot arm to its desired position by an operator, using either a joystick attached to the end effector or manipulation of a force sensor. The positions of the robot arm are then recorded in the teach pendant. It is mainly used in applications that require a continuous path such as welding. Due to the size of traditional industrial robots, it is difficult for operators to move them. However, this method has found popularity in programming lighter robots such as collaborative robots as they have joint breaks that when deactivated, allows for movement.

UR16e can withstand a payload of up to a 16 kg (35 lbs) payload. Image by Universal Robots

Advantages

- Simple programming: This method is quicker than the traditional teach pendant as it removes the need to key in instruction, allowing the operators to simply move the robot to the desired position.

- Intuitive: Operators physically move the robot arm along the application path, similar to how a human would do the task. This method also requires no knowledge of coding and 3D CAD environments. Hence, it is easy to learn.

Disadvantages

- Time-consuming: Similar to the teach pendant, this method requires the use of the physical robot to program its path, increasing its downtime. The robot has to be stopped before programming, leading to common delays. Furthermore, programming paths through this method can be time-consuming, taking days and even weeks for more complex applications.

- Lack of precision: As robot positions are hand-guided, it is difficult to use this method for applications that require high precision or high mobility in different directions. Physically moving robots can increase human errors, leading to inaccuracies.

3. Offline Programming (OLP)

Offline Programming is the programming of robots in an external computer or software outside of the work cell. Operators need not be there physically as OLP allows for programs to be designed without needing the actual robot.

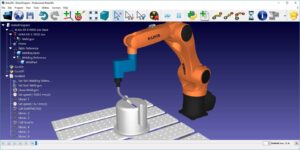

Offline simulation, an extension of OLP, allows operators to use software programs to program robots in a simulated environment. Most of these program simulators have 3D models of industrial robots, robotic work cells, and the surrounding work environment that allow operators to plan and program their robot paths without the need for the actual robot.

Due to the nature of the method, operators can explore the use of different end effectors and applications that the robot can do. If they encounter mistakes or a bug, they are able to debug and repeat the process easily until they are satisfied, thereafter programming it into the actual robot.

RoboDK’s user interface provides an interactive graphical simulation. Image by RoboDK

Advantages

- Robot agnostic: This method is able to program many different types of brands under one common interface.

- Reduces programming time: As programming of the robot can be done anywhere, it saves time as accurate simulations can be made on the interface multiple times before deployment.

Disadvantages

- Requires technical expertise: Software is restrictive and requires users to have coding experience for basic robot programming. Users of OLP software require in-depth knowledge of CAD/CAM environments and a deep understanding of robotics.

- Limited by software and hardware: This method requires additional software to be learned and requires the purchase of hardware(computer) to work.

- Requires CAD models: An accurate 3D representation of the working environment is required to use OLP softwares optimally. However, such 3D models are often not available or accurate to the real component to be used in robot simulation.

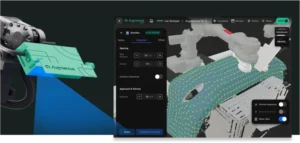

4. The Augmentus Advantage

Robotic programming has traditionally been a labor-intensive process requiring extensive expertise, manual effort, and precise calibration. Augmentus addresses these challenges by providing an intuitive solution that automates complex programming tasks. With features like advanced 3D scanning, path optimization, and offline simulation, it minimizes errors, enhances precision, and reduces downtime.

How Augmentus Works

1. 3D Scanning Integration

Augmentus integrates advanced 3D scanning technology to automatically digitize physical workpieces into accurate 3D models. This eliminates the need for CAD files or manual processing. The digitized models are immediately available within the software, where users can directly program robotic tasks. This automation streamlines setup workflows, ensuring precise geometries are captured without human intervention.

2. AutoPath for Simplified Programming

AutoPath simplifies robotic programming by generating optimal tool paths based on the geometry of the scanned model. The generated paths adhere to specific process requirements and can be adjusted as needed. This feature reduces programming time significantly and minimizes the reliance on manual fine-tuning, enabling efficient handling of complex or high-mix part geometries.

3. Path Optimization

Augmentus includes a Path Optimizer that ensures consistent tool velocity and resolves common kinematic challenges such as singularities, reachability issues, and collisions. By synchronizing multi-axis movements and optimizing trajectories, the software achieves precise and efficient operations. Engineers can customize constraints, such as limiting wrist motion to prevent cable damage or prioritizing linear rail motion for smoother tasks like spraying.

4. Offline Programming and Simulation

Offline programming is a core feature of Augmentus, enabling engineers to simulate and validate robotic programs without disrupting active production. This feature significantly reduces trial-and-error adjustments and ensures that programs are optimized before deployment. By avoiding interruptions to production lines, offline simulation minimizes downtime and enhances system throughput.

5. Seamless Code Generation

The software supports code generation compatible with major robot brands, including ABB, KUKA, Yaskawa, and Universal Robots. This ensures smooth transfer from simulation to execution, with precise translation of programmed paths into operational robot movements. Engineers can seamlessly integrate the solution into existing workflows, reducing the need for system reconfiguration.

6. In-Situ Part Correction

Augmentus addresses real-world variations by compensating for positional and rotational deviations during production. The in-situ part correction feature ensures that the robot adjusts to actual conditions, maintaining high precision without requiring manual adjustments. This functionality is particularly critical for operations involving dynamic or less predictable environments.

7. Closed-Loop Automation

Augmentus’ closed-loop automation provides continuous inspection and verification throughout surface finishing. This approach enables precise, localized treatments and ensures consistent quality, particularly in high-variability tasks like surface finishing, defect correction, and coating applications. By integrating continuous inspection and verification, closed-loop adaptive robotics reduces errors, minimizes overprocessing, and eliminates the need for manual intervention, making it ideal for industries requiring high precision and reliability.

Key Benefits

Reduced Downtime

Offline programming and simulation ensure that production lines remain operational during program development. The ability to test and refine robotic programs in a virtual environment reduces trial-and-error on the shop floor.

Improved Integration

Augmentus is compatible with a wide range of robot brands and models, allowing easy retrofitting into existing setups. This reduces integration time and costs while ensuring scalability for future applications.

Enhanced Precision

The combination of Path Optimizer, in-situ correction, and closed-loop automation provides engineers with the tools to maintain consistent precision even in complex or dynamic operating conditions.

Optimized Workflow

Automated path generation and multi-axis synchronization reduce manual programming effort, allowing engineers to focus on higher-value tasks. The system’s adaptability to specific constraints, such as limiting base motion or adjusting for part stability, ensures fine-tuned control over robotic operations.

Conclusion

Augmentus is engineered to meet the challenges of high-mix, high-complexity manufacturing environments by providing a robust, scalable, and precise robotic programming solution. Its advanced features, including 3D scanning, path optimization, and offline simulation, are designed to streamline workflows, enhance operational accuracy, and reduce downtime. For engineers seeking to optimize robotic systems, Augmentus provides a practical and efficient solution adaptable to diverse industrial needs.

If you are in need of an easier and faster way to program your robots, Book a demo today!

About Augmentus

Augmentus pioneers industry-leading robotic technologies that enable easy and rapid robotic automation, enabling anyone, even those with no robotic experience, to program dynamic industrial robots in minutes. Our proprietary technology incorporates algorithms to enable fully automated robot path generation and an intuitive graphical interface that eliminates the need for coding and CAD files in robot teaching. Companies using Augmentus have experienced up to 70% cost reduction and 17 times faster deployments across a wide variety of applications, such as spraying, palletizing, welding, and inspections. Augmentus ushers in a new era of human-machine interface, democratizing robotic automation.

References

- [1] 3 Basic Robot Programming Methods

https://www.ballerstatus.com/2021/01/28/the-3-basic-robot-programming-methods/ - [2] What are the different programming methods for robots

https://blog.robotiq.com/what-are-the-different-programming-methods-for-robots - [3] Robot Programming Methods Pros and Cons

https://robodk.com/blog/robot-programming-methods-pros-and-cons/