table of contents

- Heading 1

- Heading 1

- Heading 1

share this

Introduction

Industrial robots have transformed manufacturing by automating repetitive and hazardous tasks. For decades, teach pendant programming has been the default approach for setting up robot motion and logic. It is often perceived as cost-effective and straightforward. Yet as manufacturers face growing pressure to deliver more customized products at shorter lead times, the hidden costs of teach pendant programming are becoming harder to ignore.

This paper examines the true operational and economic impact of teach pendant programming—highlighting why companies are increasingly exploring alternative approaches to maintain competitiveness and flexibility.

Key Takeaways

- Downtime dwarfs labor costs. In high-complexity scenarios, the opportunity cost can exceed $3 million per robot annually.

- Complexity amplifies impact. As processes grow more intricate, manual reprogramming becomes a structural barrier to profitability.

- High-Mix Production Magnifies Costs. For manufacturers producing multiple SKUs or custom parts, these expenses scale linearly with each product variation.

What Is Teach Pendant Programming?

Teach pendant programming is an online method for configuring robot motion and operations. Using a handheld controller—the teach pendant (Fig 1) —operators drive the robot manually to each position in its intended process path.

Figure 1: Examples of teach pendants[1]

When operators utilize teach pendant programming, the following steps are conducted:

Manual Control of the Robot

When programming begins, the operator places the robot into manual mode, which immediately halts all ongoing operations. In this state, the teach pendant assumes exclusive control of the robot. As a result, the robot stops executing any production tasks and can only be moved via direct inputs from the pendant interface.

Moving the Robot

The operator guides the robot to the desired positions in space using the teach pendant. There are two primary methods for doing so:

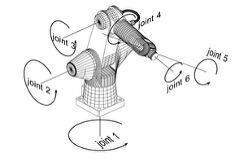

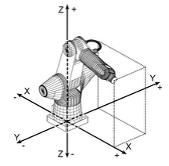

Figure 2: Joint movement[2], Figure 3: Cartesian movement[3]

- Joint Control (Fig. 2): Each joint is rotated individually to position the robot. This method allows for precise adjustments and is particularly useful when maneuvering in confined or complex workspaces.

- Cartesian Control (Fig. 3): The robot’s end-effector is moved along the X, Y, and Z axes in a more intuitive, straight-line path. Cartesian control simplifies spatial planning and is often preferred for applications that require linear motion.

Point-by-Point Teaching

Figure 4: Example of a teach pendant user interface with recorded waypoints

Once a position has been reached, the operator records it as a waypoint (see Fig. 4). These waypoints collectively define the robot’s path and the actions it will perform.

At each waypoint, the operator can configure:

- Actions: Assign specific tasks such as picking, welding, cutting, or drilling.

- Movement Speed: Specify the velocity between waypoints. This is critical in processes like welding, where consistent speed directly affects quality.

- Movement Type:

- Linear Motion: The robot travels in a straight line between points.

- Point-to-Point (P2P): The robot moves along the fastest path, which may involve curved trajectories when absolute path precision is less important.

Command Sequencing

After all waypoints are established, the operator programs the sequence of actions and logic that form a complete routine. Common commands include:

- Wait Commands: Instruct the robot to pause for a defined period. This is often used to allow time for tasks such as vacuum gripping to secure a part.

- Conditional Statements: Define logic-based conditions that trigger different actions. For example: If an object is detected, proceed to the next waypoint.

Trial-and-Error Refinement

With the initial program created, the robot is switched into test mode for verification and refinement.

Operators carefully observe each step of the motion to check:

- Path Accuracy: Are all waypoints correctly positioned?

- Collision Risks: Does the robot avoid all fixtures, tooling, and nearby structures?

- Process Quality: Are tasks like welding, gluing, or picking performed accurately and at the correct speed?

- Timing and Logic: Are wait times sufficient, and do conditional commands operate as intended?

This refinement phase is inherently iterative. Operators often need to:

- Add or remove waypoints.

- Reposition points for better accuracy.

- Adjust speeds and motion paths.

- Modify logic commands and timing.

- Re-run the program multiple times to validate each change.

Commencement of Operations

Once the program has been refined to meet process requirements and safety standards, the robot can be switched back into automatic mode to resume production operations.

Advantages and Limitations

Teach pendant programming has long been the dominant method[4] for programming industrial robots, with 90% of robots programmed this way.[5] While it offers simplicity and direct control, it also imposes significant limitations — especially in modern, flexible manufacturing environments.

Advantages

| Direct, Visual Feedback |

|

| Universal Compatibility |

|

| Minimal Setup Requirements |

|

| Precision Control |

|

Limitations

| High Downtime |

|

| Limited Flexibility |

|

| Operator Dependence |

|

| No Simulations or Process Optimization |

|

| Error-Prone Adjustments |

|

These constraints have remained largely unchanged for decades, even as production demands have evolved.

The Economic Cost of Teach Pendant Programming

These constraints have remained largely unchanged for decades, even as production demands have evolved.

In today’s world where high-mix and high variability products as well as just-in-time production are becoming more common, companies would need to alter their robots’ program every time the product changes. This means that companies that adopt teach pendant programming may lose out due to the time need to reprogram robots offline. However, how much do these companies lose out on?

We can calculate the amount of economic cost by calculating the cost incurred per year per machine due to reprogramming. This can be broken down in terms of

- Salary given to programmer to reprogram

- Missed revenue due to reprogramming

With this, we can calculate the economic cost with the following assumptions

| Complexity | Hours per Reprogramming | Programmer Cost per Hour | Parts Produced per Hour | Missed Revenue per Part | Parts change per month |

| Low | 1.5 | $70 | 120 | $100 | 2 |

| Medium | 10 | $70 | 20 | $500 | 2 |

| High | 28 | $70 | 2 | $2500 | 2 |

The workings are as follows:

Salary given to programmer to reprogram per year = Hours taken to reprogram x salary per hour x No. of reprogramming per month x 12 months

Missed revenue due to reprogramming per year = Hours taken to reprogram x Missed revenue per part x No. of reprogramming per month x No. of parts produced per hour x 12 months

With this, the following costs are calculated for each level of complexity for the manufacturing process

| Complexity of process | Cost of labour per year | Cost of missed revenue per year | Total cost per year |

| Low | $2,520 | $432,000 | $434,520 |

| Medium | $16,800 | $2,400,000 | $2,416,800 |

| High | $47,040 | $3,360,000 | $3,407,040 |

As seen, the cost of teach pendant programming is mainly composed of cost of missed revenue. This is because a lot of time is taken up in programming, calibrating and tweaking the program which requires production to stop for extended periods of time.

Conclusion

While teach pendant programming has historically offered a low-entry barrier to automation, its limitations—costly downtime, lack of flexibility, and operator dependence—present significant hidden costs in high-mix, high-variability production environments.

As manufacturers rethink how they deploy and scale robotic automation, approaches that combine intuitive, no-code interfaces with automated path generation and vision-based part recognition are emerging as compelling alternatives. For high-mix, high-variability (HMHV) manufacturers, alternatives to teach pendant programming include offline programming[9] solutions as well as more advanced vision-based or AI-enabled programming[10]systems, which can significantly reduce downtime and programming complexity.

These methods not only cut programming time and opportunity costs but also help organizations adapt more quickly to customer demands without compromising on consistency or productivity.

Solutions such as Augmentus, which integrate no-code programming, 3D scanning, and adaptive motion in a single environment, illustrate how this new generation of automation can bridge the gap between flexibility and efficiency in real-world production.

Schedule a demo today to explore how Augmentus can help you reduce programming time by up to 90%, increase consistency across your production line, and unlock measurable ROI—without the complexity.

[1] Tuttle, L., 2020. Long live the robot teach pendant. Assembly Magazine, 2 December. Available at: https://www.assemblymag.com/articles/96022-long-live-the-robot-teach-pendant [Accessed 17 June 2025]

[2] Teach Pendant User Guide, n.d. [PDF]. jpa.kapsi.fi. Available at: https://jpa.kapsi.fi/stuff/other/crs_robot/Teach%20Pendant.pdf [Accessed 18 June 2025]

[3] Teach Pendant User Guide, n.d. [PDF]. jpa.kapsi.fi. Available at: https://jpa.kapsi.fi/stuff/other/crs_robot/Teach%20Pendant.pdf [Accessed 18 June 2025]

[4] British Automation and Robot Association, “Robot Programming Methods,” 2021. https://www.ppma.co.uk/bara/expert-advice/robots/robot-programming-meth ods.html (accessed 18 June, 2025)

[5] Wilkins, J., 2020. Comment: Understanding the methods of robot programming. Manufacturing Digital, 16 May. Available at: https://manufacturingdigital.com/technology/comment-understanding-methods-robot-programming [Accessed 18 June 2025].

[6] G.B. Rodamilans, E. Villani, L.G. Trabasso, W.R. de Oliveira, R. Suterio, A comparison of industrial robots interface: force guidance system and teach pendant operation, Ind. Robot An Int. J. 43 (5) (Jan. 2016) 552–562, https://doi. org/10.1108/IR-02-2016-0074.

[7] G.F. Rossano, C. Martinez, M. Hedelind, S. Murphy, T.A. Fuhlbrigge, Easy robot programming concepts: an industrial perspective, in: 2013 IEEE International Conference on Automation Science and Engineering (CASE), 2013, pp. 1119–1126, https://doi.org/10.1109/CoASE.2013.6654035.

[8] M. Komori, T. Terakawa, I. Yasuda, Operability Evaluation System and Comparison Experiment of Gesture Operation and Button Operation of Robot Manipulator, IEEE Access 8 (2020) 24966–24978, https://doi.org/10.1109/ ACCESS.2020.2970761.

[9] Derbenwick Miller, J., 2021. Calculating the ROI of offline robot programming software. Robotics Tomorrow, 7 October. Available at: https://www.roboticstomorrow.com/article/2021/09/calculating-the-roi-of-offline-robot-programming-software/17533/ [Accessed 23 June 2025]

[10] Redress Compliance, 2025. AI in Robotic Vision: Real‑World Examples and Benefits. Available at: https://redresscompliance.com/ai-in-robotic-vision-real-world-examples-and-benefits/ [Accessed 23 June 2025].