AI Robotics Solutions for High-Mix, High-Variability Manufacturing

No-code adaptive automation for surface finishing, material removal, welding, and more.

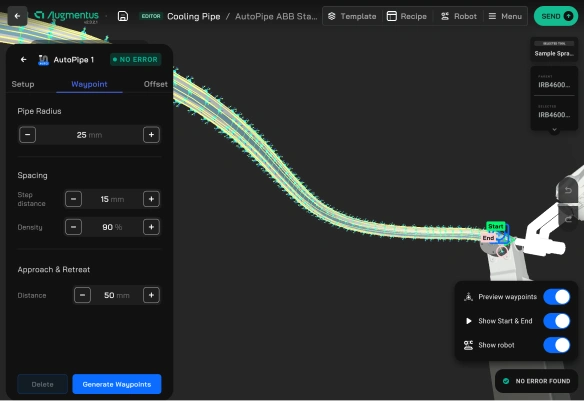

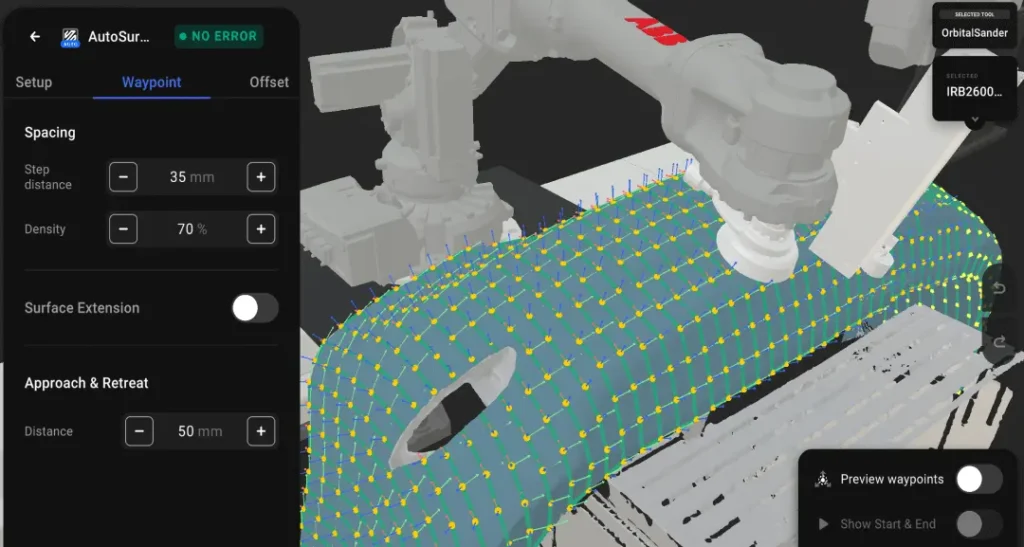

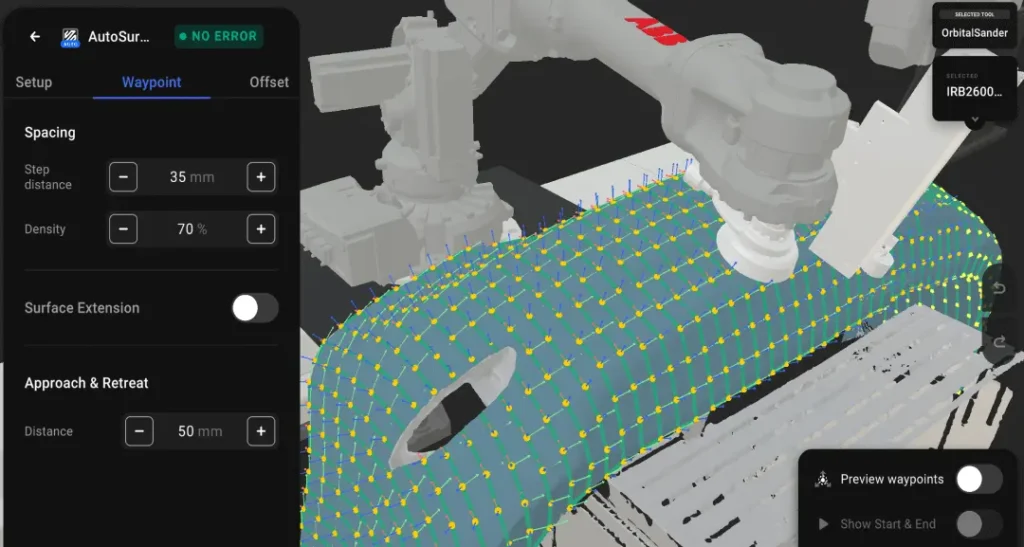

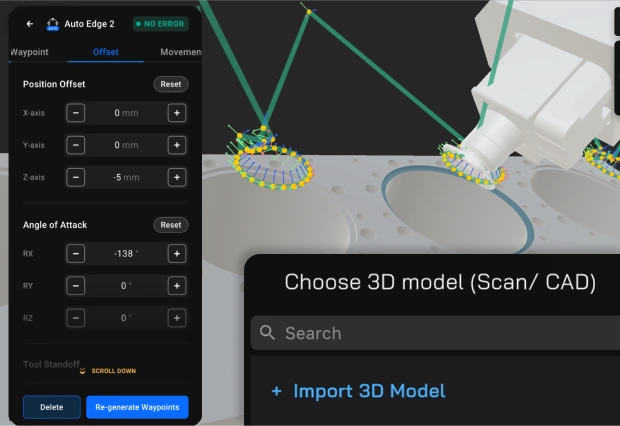

Auto-Generate Complex Toolpaths

Automatically generate complex robot motion with easy control of process parameters (i.e. angle offset, speed, and tool orientation).

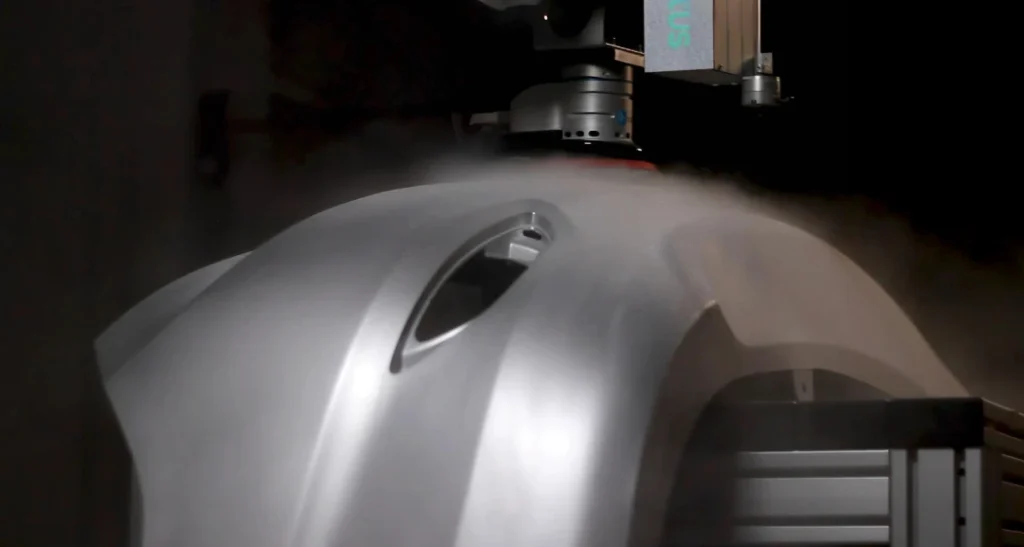

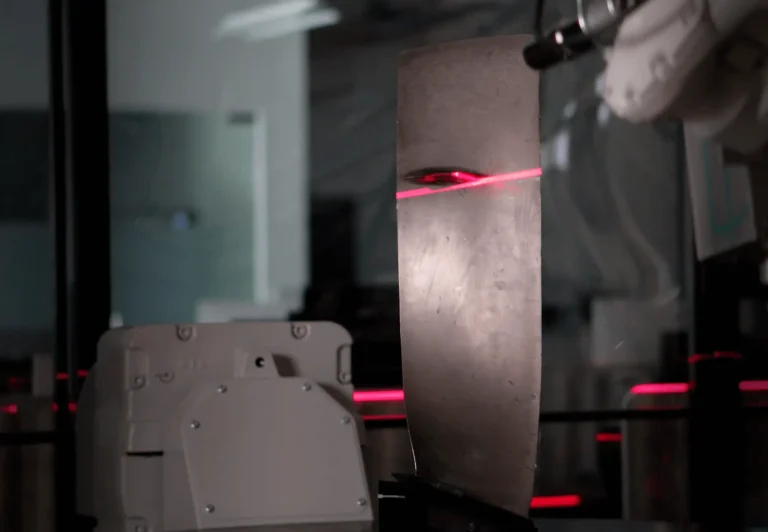

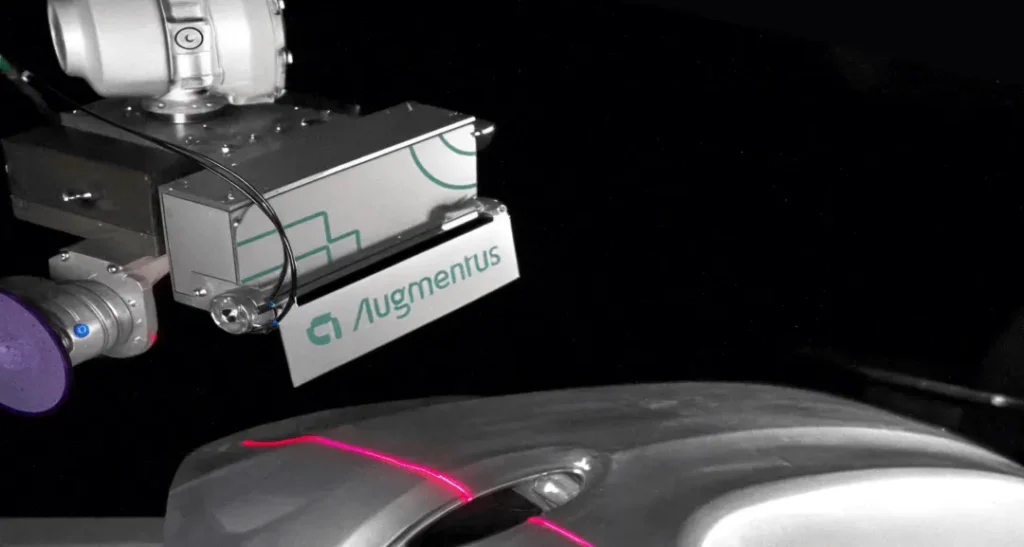

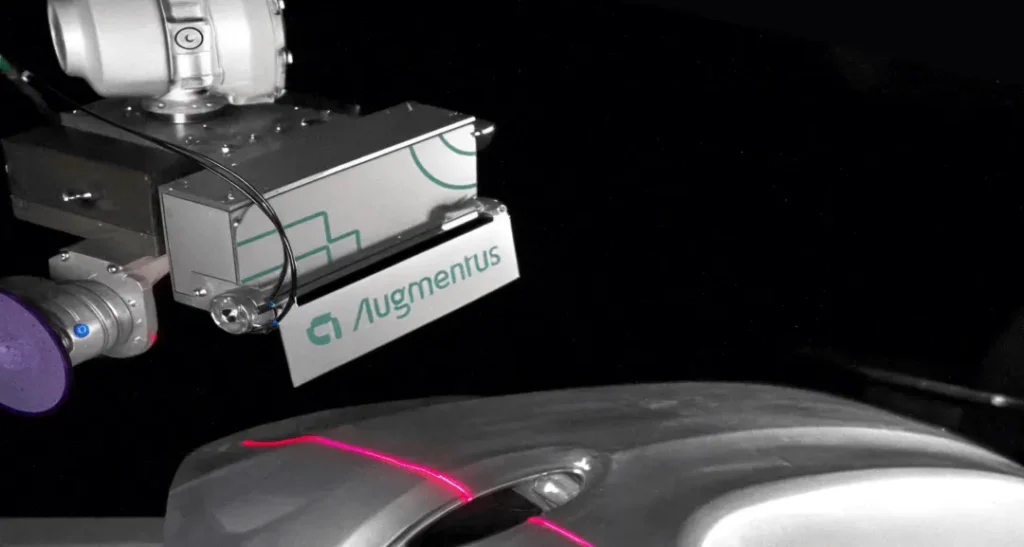

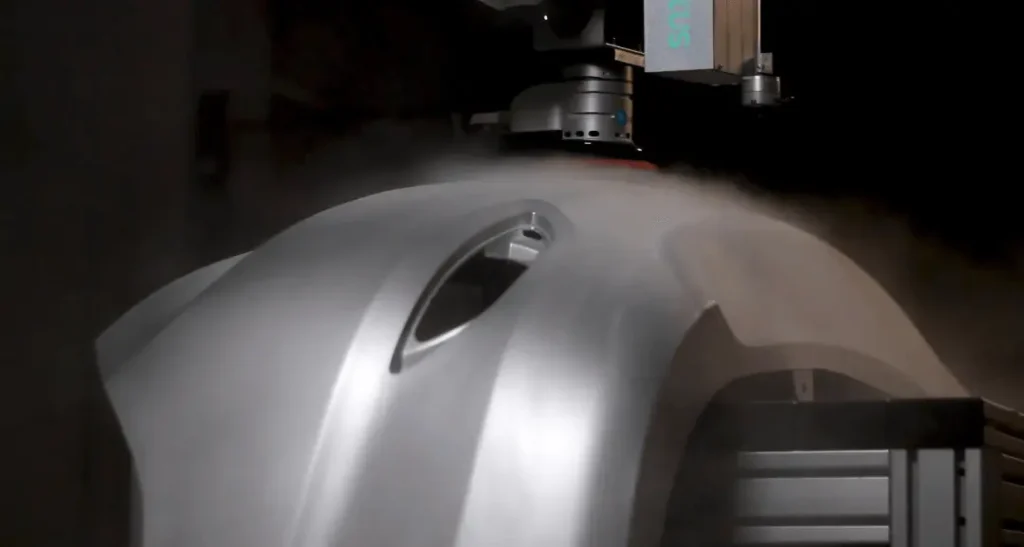

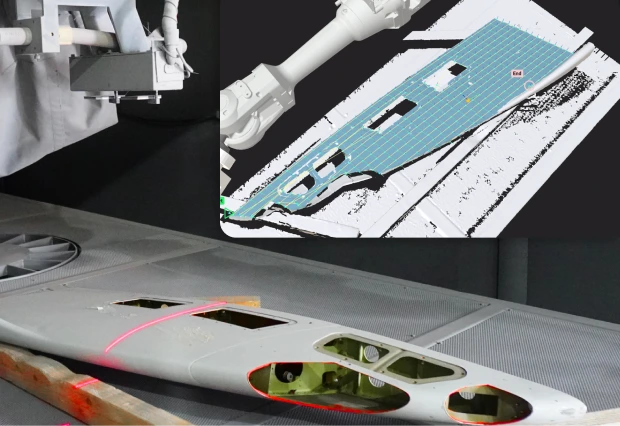

Rapid and Precise 3D Reconstruction

Capture highly accurate 3D scans of workpieces for easy programming of diverse SKUs and geometries.

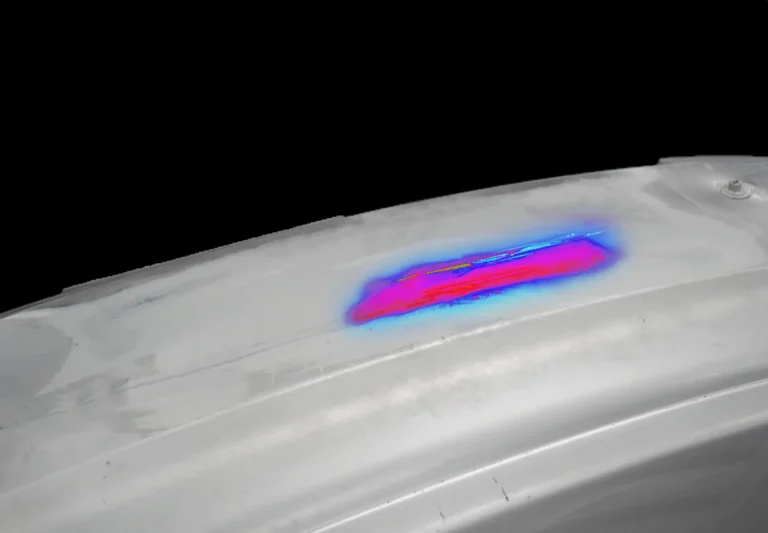

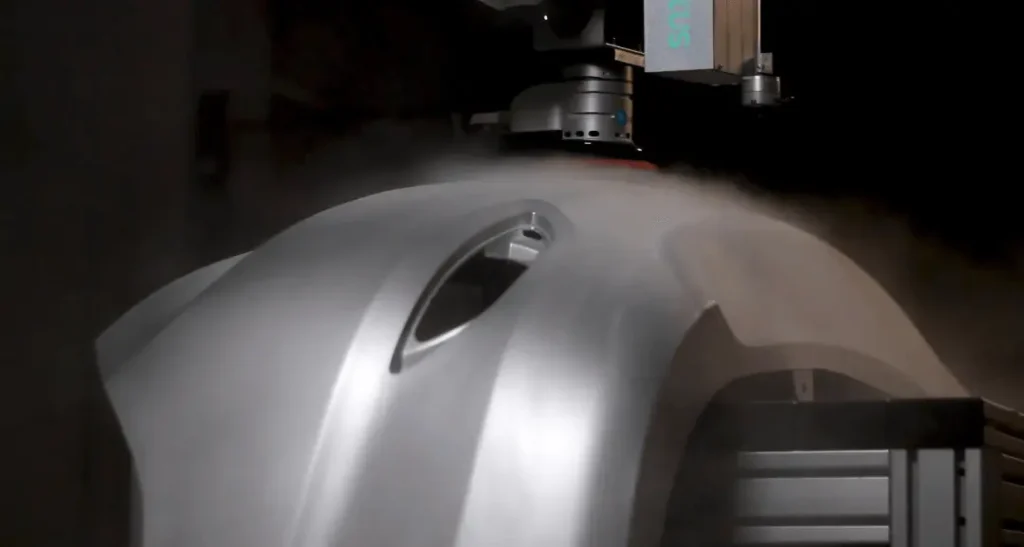

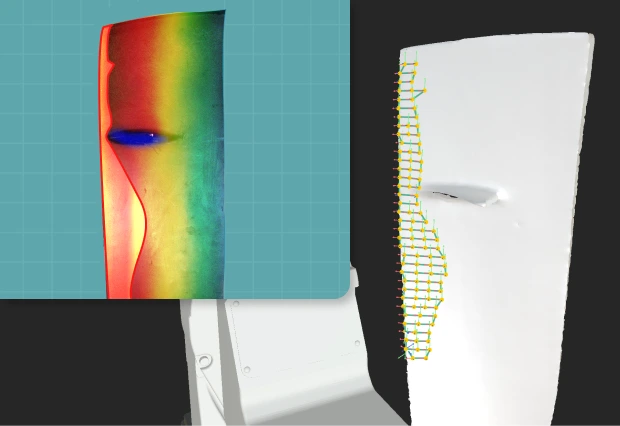

Closed-Loop Adaptive Automation

Auto-Generate Complex Toolpaths

Automatically generate complex robot motion with easy control of process parameters (i.e. angle offset, speed, and tool orientation).

Rapid and Precise 3D Reconstruction

Capture highly accurate 3D scans of workpieces for easy programming of diverse SKUs and geometries.

Closed-Loop Adaptive Automation

Automatically inspect, identify deviations, and generate precise robot motion based on inspection outputs.

Trusted by Manufacturers Around the World

High-Mix,

High-Variability Manufacturing? Solved.

Minimal Robot Downtime

Intelligent algorithms automatically generate complex robot toolpaths, minimizing robot downtime while enhancing efficiency.

Deviation Detection & Correction

A closed-loop system that automatically detects for part deviations, and corrects robot motion without manual intervention.

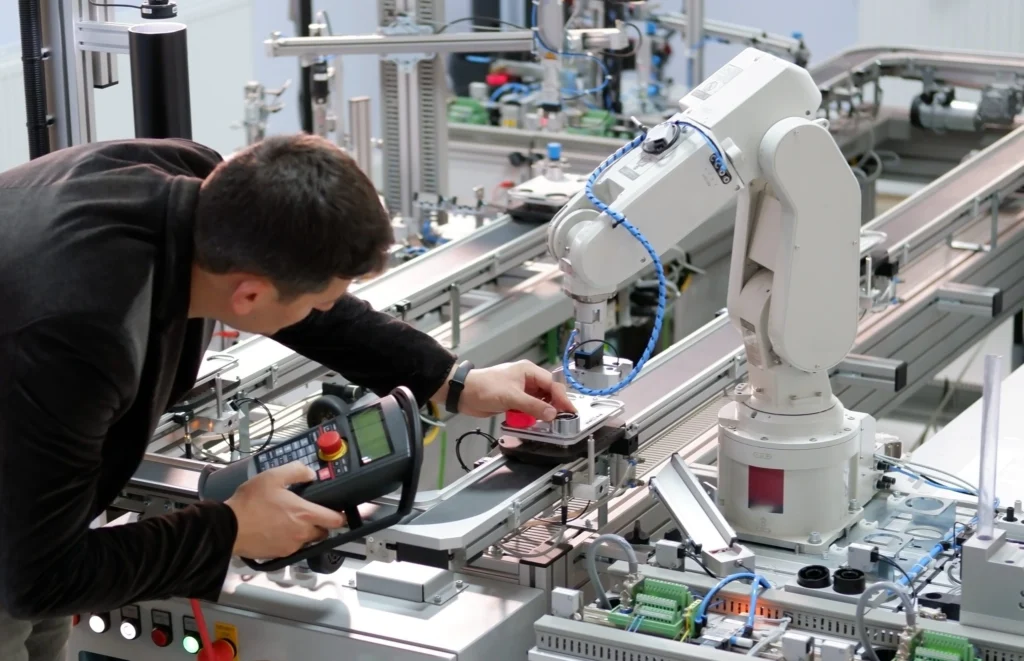

Made for Any Operator

Intuitive interface enabling operators to program robots without coding or technical expertise.

3-steps approach to robotic programming

Programming Industrial Robots Has Never Been Easier

Step 1

Scan Workpiece / Import CAD

3D scan parts with high accuracy to map complex shapes and contours for precise robot programming. Alternatively, leverage existing designs by importing CAD files of workpieces.

Step 2

Auto-Generate Toolpaths

Generate and optimize toolpaths, followed by offline simulations to preview motion before deployment.

Step 3

Deploy Adaptive Motion

Deploy adaptive robot motion that identifies part-to-part deviations for precise and consistent execution.

Augmentus advantage

Programming Industrial Robots Is Now Much Easier

Solutions for Various Applications and Industries

APPLICATIONS

INDUSTRIES

Compatible with Major Robot Brands

Explore Our Products for Your Needs

Choose between streamlined programming with Core or full autonomy with Auto

Core

Essential for Rapid Path Generation

Simplifies Robot setup and motion creation using CAD

Pro

Vision-Guided Automation

Adds 3D scanning and calibration for adaptive path generation

Auto

Closed-Loop System

Full autonomy with live toolpath correction and part variation handling