Speak with an automation expert

Our clients have experienced over 20 times faster deployments and 80% cost savings in robotic automation. Save time and manpower with Augmentus today.

-

Explore the leading solution to automating high-mix manufacturing

-

Experience easy-to-use and rapid scan and plan robotics

-

Automatically generate complex robot motion in minutes

-

Operate and program robots without prior experience

Augmentus' 3D scanning and motion planning software is easy to use for programming robots in the machines we fabricate. They have helped us to save days in programming and simulation time across our various robot cells. Best of all, it only took us a few minutes to get started!

Dave

Abrasive Engineering

MEET THE WORLD’S MOST ADVANCED

3D SCANNING &

AUTOMATED

ROBOT

PROGRAMMING

TECHNOLOGY

Augmentus solves hard challenges by combining computer vision and AI to bring intelligence to robots. With automated scan to path technology, you can focus more on advanced manufacturing and less on robotic programming, reaping substantial ROI in the process.

See Augmentus in action

SKIP THE LEARNING CURVE

All the tools you need for optimized robot path planning

Augmentus pioneers intelligent, no-code computer vision and robot motion planning, enabling industrial robot programming in minutes instead of days.

-

01/

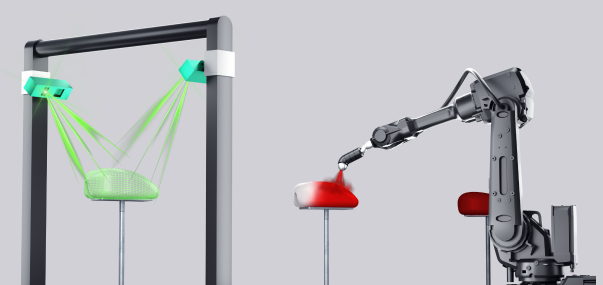

3D Vision & Computing Hardware

Augmentus vision system 3D scans parts with up to 0.1mm in precision to augment robots with intelligence and adaptability.

Augmentus vision system 3D scans parts with up to 0.1mm in precision to augment robots with intelligence and adaptability.

-

02/

AI-Powered Scan to Path Software

The leading robot offline simulation software that combines machine vision and AI to enable easy and rapid robot motion planning for even the most complex of parts and processes.

The leading robot offline simulation software that combines machine vision and AI to enable easy and rapid robot motion planning for even the most complex of parts and processes.

3D Vision & Computing Hardware

Augmentus Scanning Technology

-

Automated Scan Motion Generation

-

Automated High-eye Calibration and Localization

-

Automated Stitching of Multiple Scans

-

Seamless and Intuitive Scan-to-Path Workflow

-

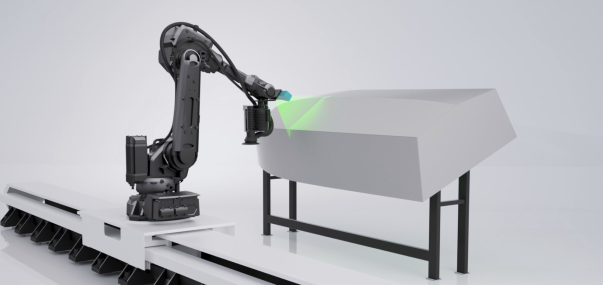

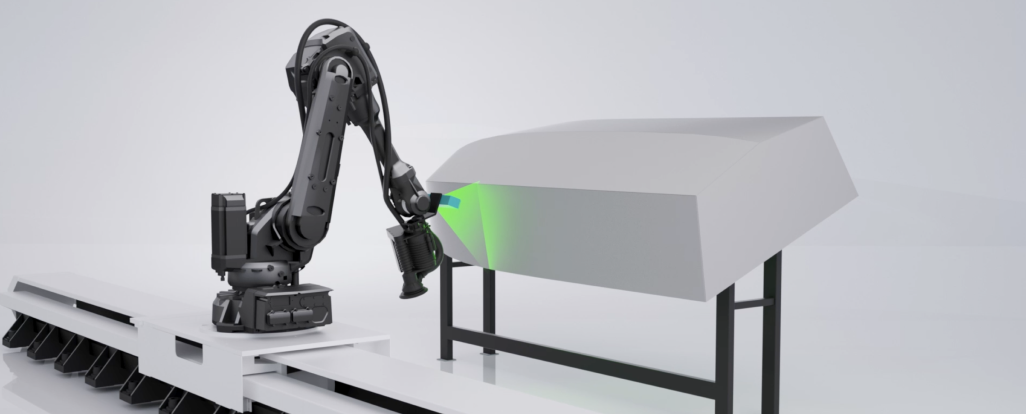

1./ Linear Scanning

Scan parts in a linear direction using gantry-mounted or robot-mounted scanners.

-

2./ Multi-Angle Scanning

For parts with complex geometry, Augmentus automatically stitches multiple scans from different angles.

-

3./ Rotary Scanning

Using a turntable or positioner, Augmentus seamlessly scans the part as it rotates.

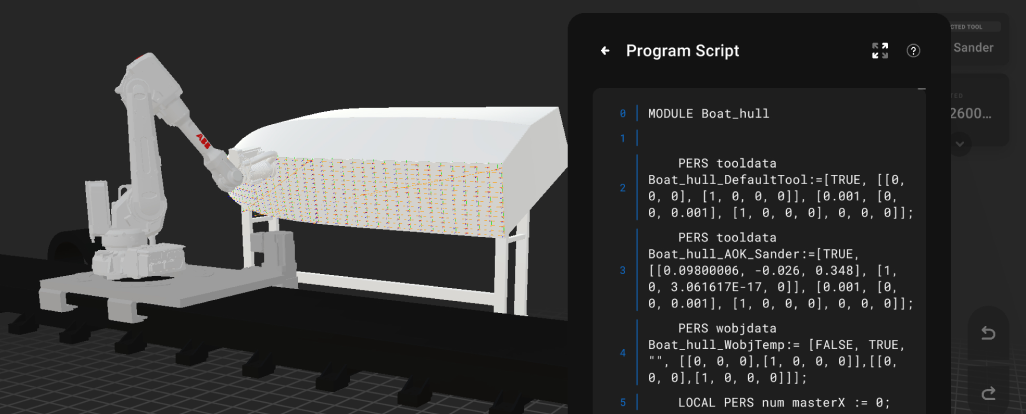

AI-Powered Scan to Path Software

The Offline Simulation Software

-

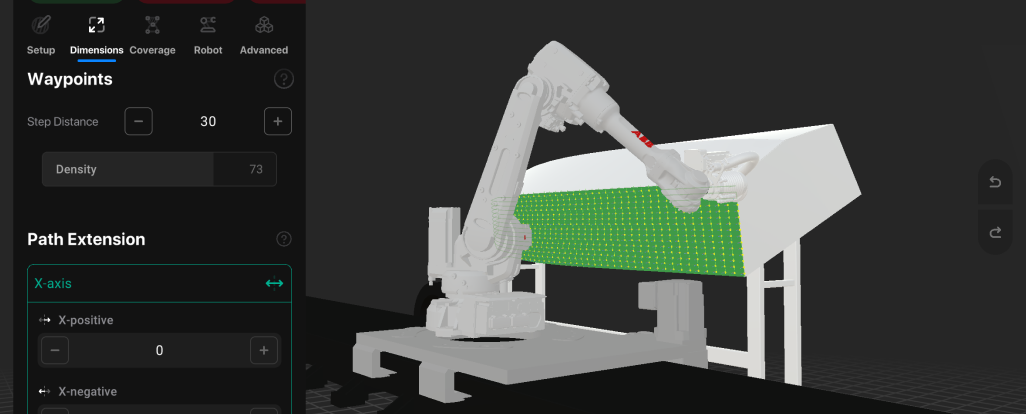

1./ Input Process Parameters

Robot operator selects surfaces / edges that they would like the robot to work on, and key in process parameters such as Auto-edge, Angle offset and Constant Velocity.

-

2./ Generate Robot Motion

Inbuilt AI and algorithms auto-generate robot motion while adhering to object geometry and process parameters. Robot motion can be fine-tuned and optimized easily by adjusting waypoints and parameters.

-

3./ Simulate u0026 Deploy

Robot motion is simulated, and robot script / code is generated specific to robot model, end-effector, sensor and peripherals. Script is transferred seamlessly to robot controller via Wi-Fi or USB.

AUGMENTUS ADVANTAGE

Fully Autonomous

Manufacturing

no programming required

To achieve a fully autonomous production, operators only need to create the master program once, which takes just minutes. After that, subsequent parts can be produced fully autonomously, with no additional programming required.

Whether dealing with high-mix or complex surfaces and edges, Augmentus offline robot programming software empowers you to seamlessly automate your manufacturing processes, drastically reducing production time from days to mere minutes.

-

01

3D Scanning in Seconds

Create digital twin of the working environment using the Augmentus Vision system. Capturing the 3D profile of the work piece in real-time and with high accuracy (up to 0.1mm) aids in accurately defining the work area.

-

02

Automated Path Generation

For the first time that the operator has to build a master program, it can be done in minutes.

Simply select the surfaces, and the system will automatically detect the surfaces to be worked on. Process parameters can be effortlessly adjusted and customized according to customer needs.

-

03

Offline Simulation Environment

The system also facilitates simulation of robot paths, enabling meticulous planning without interrupting actual production. Simulation allows for visualization and fine-tuning of robot paths, and ensuring there are no collision, reachability and singularity errors.

-

04

Deploy & Adapt

Even after deployment, Augmentus' robot programming software continuously corrects part-to-part deviations and offsets, ensuring a fully autonomous production workflow.

Operator Workflow

For brand new parts, operator builds the master program

Key Features and Functionalities

Myriad of capabilities at your fingertips with the Augmentus Robotic System, elevating your experience and maximizing productivity.

Scan to Path Features:

-

Rapid 3D Scanning

With submillimeter accuracy.

-

Advanced Algorithms

For automated robot generation.

-

Process Parameters

That is application-specific.

-

Autonomous Calibration

Of robot and its environment.

-

Error Check Tools

Check and correct programs for reachability, singularity and collision.

-

PLCs & I/Os

All synchronized for enhanced controls & capabilities.

-

Recipe Table

For quick tweaking of process parameters.

-

Inspection and QA

For part measurements and defects.

-

External Axes

Are supported (i.e. linear, rotary).

-

Inbuilt 3D tools

To ensure seamless usage of mesh.

-

Offline Simulation

For accurate cycle-time and robot motion checks.

-

Automate Faster 5X Throughput

Design, deploy and optimize robot systems in minutes without needing robot engineers.

5X

-

Dedicated 24/7 Support

You will never be without technical support when utilizing an automated scan & plan solution from Augmentus.

24/7

-

High ROI < 6 Months Payback

By drastically reducing downtime and engineering cost in robotics, manufacturers experience high returns within Augmentus’ no-code software solutions.

< 6 Mths

Turnkey or Retrofit for New & Existing Robots

Augmentus offers turnkey and retrofit solutions with just 2 days of installation time. Quickly extend robotic lifespan and improve functionality through automation.

-

[Traditional Method]

Hire Robot Engineer –> Purchase Software –> Obtain CAD Files –> Code –> Calibrate –> Optimize -> Deploy

-

[The Augmentus No-Code Robotic Software Advantage]

Scan –> Generate Robot Motion -> Deploy

Seamlessly Compatible with Leading Robot Brands

Augmentus supports a wide variety of robot brands, sensor, equipment and end-effector, enabling seamless integration and automation.

Applications

Augmentus Intelligent No-Code Software is Ideal for:

Our Users