INTRODUCING

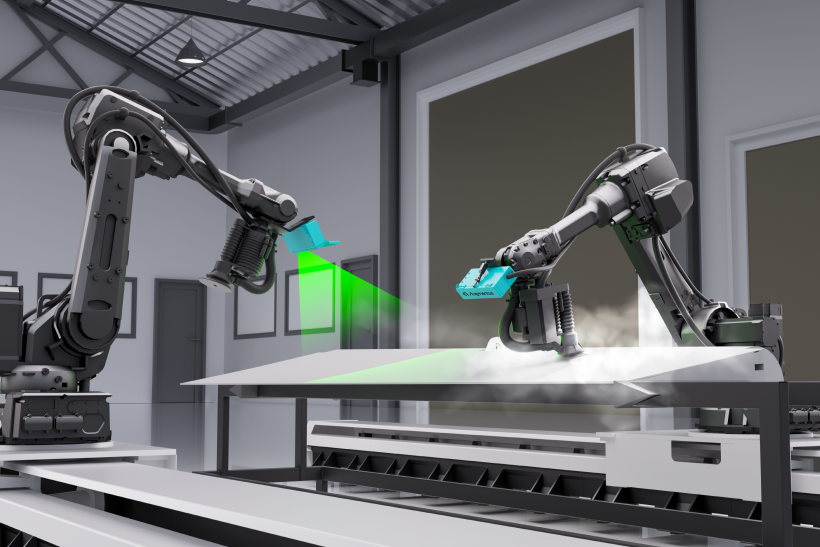

SCAN TO FINISH

ROBOTICS

Augmentus' scan to finish robotics is a solution suited for applications such as:

- sanding

- polishing

- grinding

and many more.

Existing Challenges in Finishing Automation

Manufacturers dealing with finishing processes such as sanding, polishing and grinding often encounter several limitations and struggles with conventional robot programming:

-

Complex Geometry

Finishing treatments like sanding and polishing are commonly used for intricate or irregular surfaces, making traditional robot programming intricate and time-consuming. Writing and optimizing the code to address variations in shapes and surfaces can be challenging, demanding specialized skills and significant man-hours. Conventional automation faces limitations in adaptability and precision, further complicating the process.

-

Difficulty in Handling Variability/Deviations

Manufacturing environments often have variations and deviations in part geometry, material properties, and surface conditions. Conventional programming may struggle to handle these variations effectively, leading to inconsistent results.

-

High Mix Automation

Companies often look for ways to do High Mix or small run batches, and they require frequent and new configurations and programming. Whenever a change in the finishing process is required, robots need to be taken offline for reprogramming. This can impact production efficiency and increase overall lead times.

-

5 days

Is the average downtime needed for robot programming

-

>70%

Of lifetime cost of using robots is software and programming-related

Augmentus Advantage

Whether dealing with high-mix or complex surfaces, Augmentus scan to finish robotics empowers you to seamlessly automate your manufacturing processes, drastically reducing production time from days to mere minutes.

-

01 3D Scanning for Large & Complex Shapes

Our advanced 3D scanning technology captures detailed surface geometries of large and complex shapes, ensuring precise and uniform finishing. This feature is ideal for intricate designs and oversized components, providing thorough and accurate finishing.

-

02 Automated Robot Tool-Path Generation with Force Compliance

The system automatically generates optimal tool paths using sophisticated algorithms and integrates force compliance to adjust pressure dynamically. This ensures consistent sanding quality, adapting to surface variations and reducing the risk of damage.

-

03 Edge Detection on 3D Scan

Advanced edge detection capabilities on 3D scans enable precise identification of part edges and contours. This ensures thorough and careful finishing around edges, maintaining part integrity and quality.

-

04 Part-to-Part Deviation Compensation

Adjustment of robot movements based on detected deviations from standard part designs ensures uniform treatment. This feature maintains high-quality results, even with slight variations in part dimensions or positioning.

-

05 Synchronous Motion with External Axes

Synchronized motion with external axes, such as rotating tables or linear tracks, expands the robot’s range and accessibility. This allows for comprehensive finishing of complex geometries without the need for manual repositioning.

Fully Autonomous Workflow

Automate your finishing process using Augmentus' state-of-the-art robotic finishing solution:

-

01 Scan

Scan work piece (up to 0.1mm accuracy) using Augmentus 3D scanners.

-

02 Plan

Robot operator selects surfaces / edges that they would like the robot to work on, and key in process parameters. Robot motion can be fine-tuned by adjusting waypoints and parameters.

-

03 Simulate

Robot motion is simulated, and robot script / code is generated specific to robot model, end-effector, sensor and peripherals.

-

04 Deploy

Robot motion is simulated, and robot script / code is generated specific to robot model, end-effector, sensor and peripherals. Script is transferred seamlessly to robot controller via FTP or USB.

-

05 Robot Autonomously Adapt in Production

With the master program established, the system is equipped to handle subsequent parts with precision, even compensating for any deviations using the Augmentus Vision. The 3D scanner continuously monitors the workpiece during the finishing process and provides feedback to the robot. If any discrepancies are detected, the system instantly adjusts the robot's motions. This ensures consistent quality, reduces the need for manual intervention, and accelerates the entire process.

Myriad of capabilities at your fingertips with Augmentus' scan to finish robotics, elevating your experience and maximizing productivity.

-

Rapid 3D Scanning

Wth submillimeter accuracy.

-

Advanced Algorithms

Automatically detect and correct for part-to-part deviations with submillimeter accuracy.

-

Process Parameters

That is application-specific.

-

Autonomous Calibration

Automatically detect and correct for part-to-part deviations with submillimeter accuracy.

-

External Axes

Are supported (i.e. linear, rotary).

-

PLCs and I/Os

All synchronized for enhanced controls and capabilities.

-

Recipe Table

For quick tweaking of process parameters.

-

Inspection and QA

For part measurements and defects.

-

Error Check Tools

To check and correct programs for reachability, singularity and collision.

-

Inbuilt 3D tools

To ensure seamless usage of mesh.

-

Offline Simulation

For accurate cycle-time and robot motion checks.

Augmentus Scan to Finish Robotics

The world’s most advanced, intelligent and adaptive robotic system.

-

3D Vision & Computing Hardware

Augmentus vision system 3D scans parts with up to 0.1mm in precision to augment robots with intelligence and adaptability.

-

AI-Powered Scan to Path Software

The leading robot offline simulation software that combines machine vision and AI to enable easy and rapid robot motion planning for even the most complex of parts and processes.

Applications

Revolutionize Your Operations with Our Scan to Finish Robotics

Discover the Versatility and Efficiency of Our Cutting-Edge Technology Across Applications.

Learn More About Robotic Finishing

Case studies

November 15, 2021

Automating Sanding and Polishing Processes Using Industrial Robots

Discover the future of flawless finishes! Explore how industrial robots are revolutionizing sanding and polishing processes, enhancing efficiency and precision.

Industry insights

October 12, 2023

The Role of Robots in Manufacturing Automation

Discover the game-changing role of robotics in manufacturing with Augmentus. Explore the latest trends and steps to simplify robotics programming.

Industry insights

July 12, 2024

What Is A Robot Vision System?

Robotic welding uses programmable robots to automate welding, boosting precision, speed & safety in manufacturing. Learn more here.